|

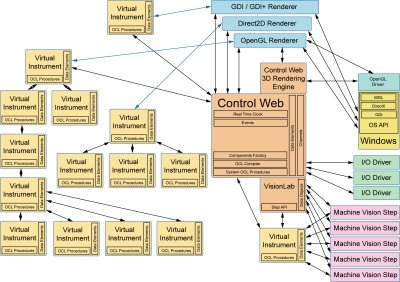

To explain the wide range of system functionality, let us recall

its concept and architecture of the software environment.

At the beginning of the development, there was a desire to use a

better system for creating custom application programs than the

so-called SCADA programs were and still remain. These programs are

considerably limited by their principles of operation, where a fixed

database loop is often cyclically serviced by a database of tags

(internal variables) and based on configuration data rendered an

operator graphical interface. The expression capabilities and

efficiency of such architectures cannot be high. SCADA programs can

serve well in the situations for which they were designed. But we want

more, today's IT world is rich and we need a freely programmable

system for our custom solutions. However, it is too laborious to

program every application from scratch, even if we take full advantage

of object-oriented programming languages.

If we take a closer look at the principles of most of today's

modern conceived program systems, we find that it is usually a

structure of program components that work together and communicate

with each other through defined program interfaces. The basic idea

behind the creation of the Control Web system is to create a set of

program components and then simply compose application programs from

instances of these components. The great strength of this concept in

Control Web is that the basic type of component we call a virtual

machine has no limitations in functionality and features, or in

quantity. The system does not know what all virtual instruments do -

in applications we use simple virtual instruments such as a button or

measuring instrument, as well as complex components such as a web

server, SQL database, stereoscopic camera or neural network. The

Control Web system only needs to be able to detect virtual appliance

components in external dynamic link libraries that are not limited in

their names or quantities again, and then manufacture component

instances and supply them for application program construction

purposes. Component instances exist in structures through which events

and data flow to which components respond. The structure of the

application program in the computer memory is thus practically

identical to the structure of a program that would be created in C ++.

Also, this program is comparatively powerful and efficient. It is

often more powerful as reusable components are carefully tuned and

optimized.

Structure of application components in Control Web

environment In addition to identifying and instantiating usable components, the

Control Web core handles event distribution, including real time,

maintains global data element and channel data, and secures

communication in a networked environment.

The application program then consists of a structure of

components, which can be:

virtual instruments - their functionality is

virtually unlimited, they can do anything, and there are many such

instruments in applications graphics renderers - for virtual machines, they

provide general abstract access to graphical features regardless of

the specific graphics API of the operating system input / output device drivers - provide

communication with the outside world in the form of input and output

units, PLCs or software standards such as OPC UA etc. machine vision steps - machine vision algorithms

above the image provided by camera virtual instruments

Při tvorbě aplikačního programu nejsme spoutání žádným předem

naprogramovaným systémem, vytváříme zcela unikátní vlastní strukturu

se svými algoritmy. To nám skýtá značné, prakticky neomezené možnosti.

Určité riziko spočívá pouze v tom, že náš program nebude dělat to co

chceme, ale pouze to, co jsme naprogramovali :-). Vždy ale vznikne

paměťově bezpečný a stabilní aplikační program. Můžeme velice

jednoduše tvořit programy v širokém rozsahu informačních a

automatizačních technologií. Nemusí to rozhodně být jen tradiční sběr

dat a operátorská rozhraní, ale mohou to být např. webové aplikace

včetně redakčního rozhraní, databázové aplikace se vstupními formuláři

a výstupními sestavami, aplikace přímého řízení strojů a výrobních

linek v reálném čase, aplikace kamerového dohledu, vizuální inspekce a

komplexní systémy strojového vidění a mnoho dalšího. Fantazie tvůrců

aplikací není nijak omezována. Přitom většinu vývoje lze udělat pouze

pomocí myši v grafickém vývojovém prostředí. Především však můžeme

vytvářet spoustu velmi rozdílných aplikací v jednom vývojovém

prostředí. Ušetříme spoustu práce a času - nemusíme se učit několik

programovacích standardů a nemusíme ovládat několik programů a

konfiguračních nástrojů.

Applications are built according to the principles now

promoted as Industry 4.0

It is quite interesting that many of the concepts for building

smart production systems, today as popular as Industry 4.0, have

been part of the Control Web architecture for a long time.

Here are some examples:

cloud and Internet of services - more than

twenty years ago, as the Control Web name suggests, both the Web

client and the server were part of the system, allowing access

to dynamic application data through Web services. The system was

designed from the outset for applications dispersed in TCP / IP

networks. It enables unified access to local data and data

anywhere in the computer network.

DataLab industrial I/O unit with Ethernet

connection to TPCP/IP network Industrial Internet of Things - the concept

of a computer is much wider than it was in the past, as it is

part of many common devices. Your computer may have a credit

card size and run Control Web. Such a device is then easily

integrated into the Internet of Things. Also, industrial DataLab

I/O units can be connected to a TCP/IP network and can be

located anywhere. E.g. the entire industrial automation

switchboard of a machine or production line can be integrated

into the system via a single Ethernet connection.

Obr 3: Automatizační rozvaděč lze díky jednotkám

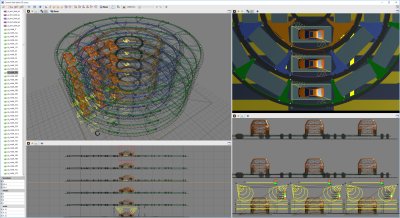

DataLab připojit do počítačové sítě virtual reality and digital models -

Although the 3D rendering system was not available immediately

from the first version of the system, in 2002 it was probably

the first before other industrial automation systems. Now in the

latest version of the system, the idea of hybrid virtual

instruments has been fully completed and implemented, which can

exist both in the three-dimensional space of the scene, as well

as in conventional panels with arbitrary graphics renderers. All

spatial visualizations can also be visualized through

stereoscopic virtual reality glasses.

Scene preparation in 3D editor - spatial models of

real devices, machines and buildings are clearer and clearer

in some applications than area diagrams cybernetic — physical systems - a device in

which Control Web is running is no longer a simple programmable

controller. In addition to controlling the machine, it can

provide the machine with a perception of the outside world

through machine vision, connect with other information systems,

databases, communicate on the Internet and make decisions using

artificial intelligence.

In a smart factory, each machine is part of a

computer network

Thanks to its network and communication, database and

visualization capabilities, Control Web maximally supports the

progressive way of controlling industrial production and

management of production equipment and machines as well as control

and automation systems solutions.

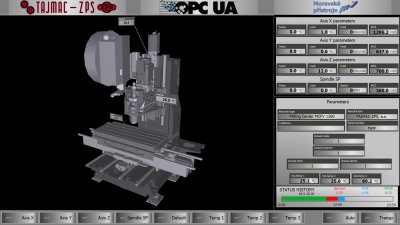

Effective solution of control and automation systems

If we have a control unit with the Control Web system in the

automation system, we can design the entire system as efficiently

as possible. For many systems, we will need nothing but a control

computer and some industrial inputs and outputs. Everything can

run in a single programming environment, so we save money not only

on PLC, but above all, we will greatly simplify and speed up

programming. In all cases, of course, you cannot do without a PLC,

but in many cases it is. When upgrading older industrial

automation systems, we often replace several PLCs with a new

control computer with new software, and at a lower cost we get

higher performance and an incomparably higher range of

functionality.

Efficient automation of the production line with

Control Web - a computer with a graphical interface for the

operator and DataLab unit for machine control connected via

Ethernet Especially significant efficiency gains are obtained in cases

where visual inspection cameras are also used. Combining machine

vision and visual inspection with all the features of the Control

Web programming environment is a high value for a smart

statement.

Open standards bring the freedom and easier maintenance and

further development

The architecture of the Control Web system is based on the use

of open standards of information technology. Reduces the risk of

being hostage providers who often use your own, closed, and

possibly world-protected communication systems, data and program

standards that are available for long-term customer attachment to

their customers. Users will then become safe hostages of these

suppliers. The efforts of large, unnamed, well-known concerns to

lock suppliers are no less intense than in the past. Only before

have all been made available openly and straightforwardly, while

more hidden and sophisticated methods can be chosen today - and

when it is possible to declare what advocates of open standards

you can now be modern and look good to say.

Developing, repairing and maintaining applications is

completely free

So we still need to invest some of our own work to create an

application program, but the development environment, including

all add-ons and extensions, is available for free. We can also

download and use any driver as well as VisionLab vision system. We

will only need a license when we deliver it to the end customer

and deploy our application into continuous operation.

Without the need to invest in any equipment, we can try what we

can create with the help of Control Web.

Roman Cagaš

|