|

The OPC Data Access became the widest spread standard for data

exchange between industrial automation devices and the visualization

and control applications. The OPC is based on Microsoft COM

technology, which allows relatively good efficiency low overhead on

the one side and good support within the operating system itself on

the other side (number of components of Windows uses COM technology,

too).

The OPS client connected to the server can choose from a number of

ways to exchange data (synchronous, asynchronous, call-back

notification), it can require data directly from the device or from

the server cache etc. All these possibilities (and also the usage of

relatively complex COM technology) makes full implementation of OPC

server rather difficult. Development of OPC server is almost

impossible for a small company without a team of experienced

programmers and also big, rich and famous companies have significant

problems with development of the server fully complying to the

standard (they are usually satisfied when the server works well with

their clients and they often omit other ways of data exchange). Number

of companies rely on various “OPC Server Toolkits” made by

third parties. This approach also often fails — although it enables implementation of the OPC server to

less-experienced programmers, an absence of in-depth understanding of

the standard prohibits the programmers to correctly implement the

server either way. If a problem occurs, programmers usually cannot

localize it, they do not know which parts of their code is called in

various contexts etc.

Moravian Instruments has wide experience in implementation of OPC

clients and servers and the development team carefully implemented the

OPC interface. On the other side the OPC Server uses the

Control Web driver interface. This interface is very

efficient (it uses direct procedural API implemented in DLLs) so there

is no other software layer between the driver and its user. At the

same time this API is universal enough to cover all devices — communication can be synchronous or asynchronous (for

devices with delayed response caused e.g. by communication delays),

the driver always knows which data elements should be transferred in

the particular time so it can optimize creation of protocol packets

etc.

The Control Web driver interface is open and well

documented. There are not only drivers implemented by Moravian

Instruments, but also number of drivers implemented by third parties.

These companies automatically gain the possibility to supply the OPC

Server for devices, for which they already implemented the

Control Web driver. If it is necessary to implement a

new OPC server for some device, it is much easier and often more

efficient to implement driver for Control Web than

starting with the OPC server from the ground up.

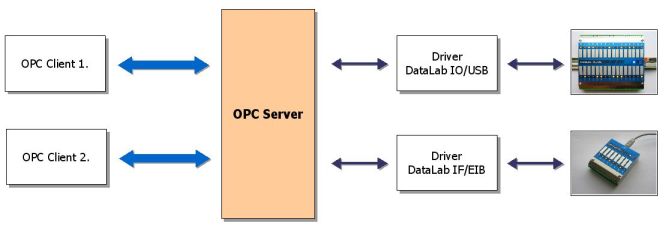

Communication between OPC client and the device through the

OPC server and Control Web driver Although the OPC server for Control Web drivers is

a licensed product, number of drivers are available for free.

Control Web driver is supplied with every

DataLab IO/USB or DataLab IF/EIB device (and also drivers in the form of

Active X component). If it is necessary to communicate with these

devices through OPC interface, the OPC Server is available for all

clients.

|