| The driver allows Control Web to communicate

with arbitrary OPC server. The driver is compatible with OPC Data Access

v1 i v2 standards published by OPC Foundation.

Contents - OPC driver for Control Web

- What is OPC

- OPC versions

- Data transfer within OPC standard

- OPC name space

- Array data items

- OPC server initialization

- Remote servers and DCOM

- OPC driver configuration files

- Parameter file

- Section [server]

- Section [channels]

- Parameter file example

- DMF file example

- OPC driver configuration tool

- Choosing the OPC server

- Choosing channels

- Assigning channel numbers

- Assigning channel numbers to arrays

- Driver parameters

- Generation of configuration files

- Loading of existing parameter file

What is OPC

OLE for Process Control (OPC) represents the first successful

movement standardizing communication interface among various

industrial automation devices (PLCs, I/O devices etc.) and SCADA,

HMI and control computers. The OPC standard is valuable mainly for

customers, who no longer depend on proprietary protocols and

communication infrastructure of the particular supplier

(especially if such companies bar third parties from

implementation of their protocols by law barriers). The OPC

standard is maintained by non-profit OPC Foundation

(http://www.opcfoundation.org/) and OPC standard can be

implemented by anybody without royalty fees.

OPC is implemented as a software layer between industrial

automation devices and software, which exchange data with such

hardware. Hardware devices equipped by OPC servers are as easily

usable as e.g. new PC graphics adapters supplied with

driver — just plug it into the computer,

install driver and it works. Similarly, If there is a suitable OPC

server for some PLC, OPC clients should be able to exchange data

this PLC.

The OPC standard is based on COM — software component technology developed by Microsoft

Corp. The OPC abbreviation suggests using of OLE (Object Linking

and Embedding) technology, build above the COM foundation. But it

is rather difficult to distinguish what part is pure COM and what

is OLE, especially when Microsoft marketing department adds new

naming, like Active X. Because Microsoft itself uses COM in

various parts of Windows operating system, the COM is widely

supported and developed and contains number of features very

useful also for OPC, like system-wide component registration

(every OPC client can easily search for all installed OPC

servers), standardized data exchange formats, event and

notification interfaces etc.

The OPC standard is relatively complex and its various parts

cover various areas of industrial automation. The very basic is

the “OPC Data Access” standard, which is also used by the

OPC Client driver for Control Web.

OPC versions

The OPC standard evolves with the growing experience with its

usage. There are two main versions of OPC Data Access — version 1 and version 2. Due to the fact that COM is

based on individual independent interfaces (groups of methods

manipulating individual components), some interfaces of version 1

were preserved also in version 2. Other interfaces were removed

and replaced by new ones and there are also newly added interfaces

in version 2.

One of the COM technology advantage is that every client can

easily determine the version of the OPC server and to use only the

interfaces defined by the particulr OPC standard version. So some

clients can be able to work with both version 1 and version 2

servers. On the other side, due to interface based API of COM

components, the server can implement all interfaces defined by

both OPC versions and thus be able to work with all clients.

The OPC standard clearly defines, which interfaces are

required, and which are optional in the particular OPC version.

The OPC server implementation, which does not support some

interface required by OPC standard, is simply wrong

implementation. This does not mean the server cannot run at

all — clients not asking for unimplemented

interfaces can work with such server without problems. But if some

client ask for the missing interface, the wrong server

implementation surfaces.

Control Web OPC Client driver can work with

both OPC version 1 and version 2 servers.

Data transfer within OPC standard

The OPC standard defines number of ways to communicate

with clients to satisfy their needs:

Synchronous communication always waiting for data

transfer from/to the device. Synchronous communication with the server cache

only. Asynchronous communication always waiting for data

transfer from/to the device. Periodical communication of the server with the device

and callback to client when data changes.

The second and the fourth point demand the server to exchange

data with the device periodically and to store read values to the

cache and, if required, notify the client (using connection point

interface) that data was changed.

Although the OPC Client driver for Control Web

works with both version 1 and version 2 servers, it uses only

synchronous transfer with version 1. Asynchronous transfer defined

in OPC Data Access version 1 suffered from number of

problems — this is why the asynchronous

transfer based on the IDataObject interface was completely

abandoned in version 2 and replaced by the more effective

asynchronous communication using IConnectionPoint interface.

Usage of the synchronous communication does not negatively

involve the Control Web application execution.

The driver always works asynchronously from the Control Web point of view and does not block the application by

waiting to the finishing of data exchange.

The asynchronous communication is used with all OPC version 2

servers by default. But it is possible to force the OPC driver to

use the synchronous communication with the version 2 servers by

setting the sync parameter in the driver parameter file (see the

PAR file description for details).

The data communication defined by the OPC standard is much more

complex and is thoroughly described in “Data Access Custom

Interface Standard, Version 2”, published by the OPC

Foundation. But it is not necessary to understand the OPC data

exchange to effectively use the OPC driver for Control Web. The driver uses OPC features which fit the

Control Web driver requirements so the user can

use all features provided to Control Web, like

time stamps, quality of service etc., and let the driver to

translate them to OPC and back.

OPC name space

Every OPC server defines some name space, which assigns the

unique name to every data item, which can be communicated. The

name space can be flat (single level) or hierarchical (structured

to the tree with branches and leafs, similar to the folders and

files structure of computer disc drives).

The OPC server may (but is not required to) provide the

interface, which enables browsing of its name space. Such

interface is very beneficial, because every read or write to any

data item defined by the server requires adding of the particular

item to some client-defined group, which requires the knowledge of

the data item's name. If the name space browsing interface is not

provided by the server, the user (and the server vendor) must

define the way of item names specification.

The OPC standard does not presumes any rules for data item

names definition. The name can contain any characters, including

spaces, special symbols etc.

Array data items

Because OPC is based on COM technology, it utilizes COM

mechanisms to transfer data. But the COM allows definition of both

simple (scalar) values and also arrays of values in the VARIANT

structure. It depends on the particular OPC server if it presents

data as scalar data items or in arrays of items.

Although the possibility to define one array instead of

definition of every item separately, it also brings some

disadvantages — it is not possible to

transfer individual elements separately. Reading and/or writing of

only a few array items requires allocation of memory for the whole

array, copying of all array items to/from the memory and passing

of the array to COM layer. This is not a problem in the case of

small arrays, but it is necessary to count up with this overhead

in the case of big arrays with hundreds or thousands of items.

But transferring of whole arrays is not defined in the driver

interface of Control Web. The reason is the

inability to optimize data transfers and to communicate only

single values mentioned above. Regardless the Control Web enables definition of arrays on the application

level. What is defined as array of channels in the application,

particular driver sees like individual channels. Any continuous

block of channels (channels numbered by continuous number

sequence) can be defined as an array in the application. It then

depends on the driver how it optimizes communication of only some

elements, which need to be updated.

If the OPC driver access array data item on the OPC server, it

maps array elements to individual channels. If the array is

multidimensional, OPC driver (in compliance with COM definition)

increments the left-most index first. That means e.g. matrix is

stored in the column order (like in Visual Basic or FORTRAN

languages) and not in row order (like in Pascal or C/C++).

To enable mapping of array to individual channels, it is

necessary to number such channels by continuous number sequence.

Syntax of the PAR file, which defines individual channels,

enforces this rule.

Because arrays are mapped to individual channels by the driver,

it is possible to define array items as individual channels, as

one array, or as any combination of arrays and individual channels

within the application (it is even possible to define array, which

overlaps the boundary of OPC array and other items/arrays, if

channels are numbered sequentially). But the OPC driver must

communicate whole arrays only and it is strongly recommended to

mirror OPC server arrays to arrays in Control Web

application. The OPC driver configuration tool (describer later),

which generates PAR and DMF configuration files, follows this

rule.

OPC server initialization

OPC servers are rather complex programs, which have to perform

possibly time-consuming initialization during startup. Such

initialization can include scanning of the Windows Registry for

parameters, configuration file parsing, allocation of internal

data structures etc. Either way, not every server can accept user

requests immediately upon startup.

There is a method through which the server can return

its state, like “not configured”, “test mode” or

“running”. But different OPC servers return their state

different way. For instance there are servers, which return

state “running” immediately upon startup, even if they

are not prepared to accept client requests. The OPC driver

includes two ways to overcome such problems:

If the server returns state “not configured”, the

OPC driver can wait until the server state changes to

“running”. The second possibility is to simply wait for defined

period after the server is launched without respect to the

server state.

Either way, the OPC driver can start work with the server only

if it returns state “running”.

Remote servers and DCOM

Part of the COM technology is the ORPC (Object Remote Procedure

Call) extension called DCOM (Distributed COM). DCOM enables

clients running on one computer to create instances and invoke

methods of servers on another computer within the network. Because

DCOM was not available when Windows 95 was introduced to the

market, it is necessary to install free DCOM support to use it on

Windows 95. But modern operating systems (Windows 2000, Windows

XP) come with DCOM included.

OPC driver for Control Web supports DCOM, so

it is possible to create OPC servers on remote computers. All data

exchange over the network is then maintained by DCOM.

Because DCOM is the network technology, it is necessary to

configure it properly from the security point of view. Users

creating COM servers on remote computers must have granted access

to such computers. If there is a firewall protecting particular

networks from attacks and IP ports used by DCOM are blocked, the

network administrator should reconfigure firewalls to enable DCOM

network traffic. All such problems must be considered when

planning DCOM usage. Detailed description of computer and network

security can be found in Microsoft documentation.

OPC driver configuration files

As all Control Web drivers, the OPC driver

needs two configuration files to run — parameter file (.PAR) and driver map file (.DMF).

The purpose of both files is described in the Control Web

documentation. The DMF format is the same for all drivers and is

described in the Control Web documentation, it is

not necessary to describe it here.

The contents of both DMF and PAR files depends on the used OPC

server and defined channels. There is a GUI tool supplied with the

driver To simplify the configuration files creation. The users

need not to know the format of configuration files — they only select the server, mark items which should

be accessible as channels for Control Web

application and configuration files are generated automatically.

The OPC driver configuration tool is described in the second part

of this documentation.

However the knowledge of the OPC driver parameter file

structure can be useful e.g. when it is necessary to edit this

file by text editor of to generate it automatically by some other

program.

Parameter file

OPC driver parameter file follows the conventions of .INI

files, which are simple text files divided to individual sections.

Each section begins with line containing section name in square

brackets, followed by lines defining individual keys in the form

key_name=key_value. OPC driver requires two sections in parameter

file: [server] and [channels].

Section [server]

This section must contain the OPC server class identifier

— CLSID. Class Identifier is globally

unique identifier (GUID), a 128-bit number used in COM to

identify various objects, like classes, interfaces, type

libraries etc. The text representation of the GUID is defined

by COM and is used as key name in the Windows Registry folder

HKEY_CLASSES_ROOT\CLSID, where all COM components have to be

registered.

CLSID={F738C006-F632-4E9E-946E-2C2CF2A418A1}

If the OPC server should be created on remote computer

using DCOM, the parameter host must be defined. This parameter

contains UNC path to the remote computer (host), where the

required server is installed and where have to be run.

host=\\remotehost

As already noted above, OPC driver uses synchronous

communication with version 1 servers and asynchronous

communication with version 2 servers (only is the version 2

server does not support asynchronous communication interface,

synchronous communication is used).

While the asynchronous communication with version 1 servers

is not supported by the driver, it is possible to use

synchronous communication with version 2 servers by setting

sync parameter to true.

sync=true

If this parameter is missing or set to false, OPC driver

prefers asynchronous communication, if possible.

If the server returns its status “not configured”

(OPC_STATUS_NOCONFIG) upon startup and after finishing the

initialization returns status “running”

(OPC_STATUS_RUNNING), it is possible to wait for the

“running” state by setting the parameter wait_running

to true:

wait_running=true

If the server needs some time for initialization (and does

not reflect its state correctly), it is possible to insert

some wait period to driver initialization. Parameter wait_time

defines number of seconds of the waiting delay:

wait_time=2.5

Section [channels]

This section contains lines each defining one channel:

channel_number=identifier of the OPC server data item

If OPC data item identifies an array, there is a channel

number interval covering all elements of the array instead of

single channel number. The first and last channel numbers are

delimited by the '-' character (channel number cannot be

negative so the '-' character is not interpreted as negative

sign).

first_channel_number-last_channel_number=identifier of the OPC server array item

Because there are no restrictions on characters used in OPC

item identifier, all characters following the equal sigh up to

end of line are considered to be part of the identifier.

Channel definition needs no more information but data

identifier, because OPC server can provide all other necessary

attributes, like channel type, possible direction (read or

write) etc.

Parameter file example

[comment]

OPCDRV PAR file created by OPC Driver Configuration Tool

File: C:\BUFF\opc.par

Created on: 04/30/2002 16:31:21

[server]

CLSID={F8582CF2-88FB-11D0-B850-00C0F0104305}

host=\\remotehost

[channels]

100=Random.Int4

101=Random.String

102=Random.UInt4

103=Random.Real4

104=Random.Real8

105=Square Waves.Real8

106=Triangle Waves.Real8

107=Write Only.UInt1

108=Write Only.UInt2

109=Write Only.UInt4

110-119=Random.StringArray

120-129=Random.Real8Array

OPC driver itself requires only sections [server] a

[channels], other sections are ignored. The section [comment]

used in this example is ignored by the driver and servers ony

for storing of some additional information. The name of this

section is not relevant, any name other than server

and channels can be used.

DMF file example

The corresponding DMF file contents is shown for

illustration purposes:

OPCDRV DMF file created by OPC Driver Configuration Tool

File: C:\BUFF\opc.dmf

Created on: 04/30/2002 16:31:23

begin

100 longint input

101 string input

102 longcard input

103 shortreal input

104 real input

105 real bidirectional

106 real bidirectional

107 shortcard output

108 cardinal output

109 longcard output

110 - 119 string input

120 - 129 lonreal input

end.

OPC driver configuration tool

It is not very easy to get the CLSIDs of installed OPC servers

by browsing the Windows Registry and obtaining item identifiers,

their types and directions and typing PAR and DMF files in text

editor is event more complicated. This is why the OPC driver

configuration tool (OPCDRVCF.EXE) is supplied together with the

driver itself. This tool enables very simple selection from all

installed local or remote OPC servers, browsing of the selected

server name space and selecting which items should be visible as

channels to Control Web application and automatic

generation of PAR and DMF files. It is also possible to copy the

text definitions of appropriate Control Web

channels to the system clipboard so the text can be very easily

pasted to the application source code in the Control Web integrated development environment.

The configuration tool main window contains two panes — left pane shows a tree of the selected server name

space, right pane contains sheet with selected items.

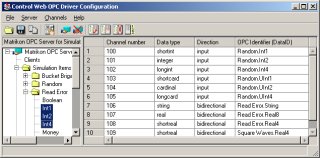

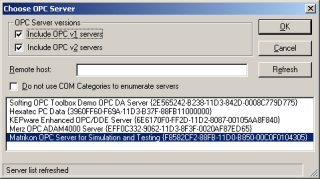

OPC driver configuration tool window Choosing the OPC server

First it is necessary to select the OPC server, with which

the driver should communicate. Menu Server/Connect to OPC

Server... opens a server selection

dialog.

Choose OPC server window This dialog shows names and corresponding CLSIDs of all OPC

servers installed on local or remote computer. It is possible

to restrict the displayed OPC servers to version 1 or version

2 only. Many servers provide all interfaces of both versions

so they will be displayed in both cases. The OPC driver

configuration tool searches OPC servers according to COM

Component Categories, which is the standard COM component

identification mechanism. The OPC Foundation defined two

globally unique identifiers (GUIDs) for OPC DA Server v1 and

v2 categories. It is necessary to register particular category

and to assign appropriate category GUID to installed server

during installation process. But there are servers, whose

installation programs ignore this rule. This is why there is

the check box Do not use COM Categories to enumerate

servers in the dialog box. If the box is checked, the

presence of the OPC key in the Registry is used

for distinguishing OPC servers instead of COM categories. The

list of found servers then can contain components, which are

not OPC servers and an attempt to connect to such component

will lead to error message. On the other side, such option

enables to work even with wrongly installed server.

Choosing channels

If the server is successfully created, the left pane shows

its name space. Individual items can be added to the channel

list (the right pane) by double-clicking them or it is

possible to select more items at once and add all selected

items to the channel list using menu Channels/Append

selected items. Channel can be removed from the list

after selection of the whole channel line by clicking the box

on the left side of the line and pressing the <Del>

key or it is possible to use menu Channels/Delete

selected channel. It is also possible to clear the

channel list using menu Channels/Clear all

channels.

Some servers cannot provide valid information about their

name space immediately upon startup (and do not reflect this

state in the server status). This can cause the name space

tree appears not complete. Simply choose the same server

again, now the server is already running and the name space

tree should be complete.

The configuration tools tries to obtain information about

the data type (integer, string, etc.) and communication

direction (read, write, bi-directional) for each channel from

the server. Unfortunately there are some servers, which do not

provide such information at all or do not provide this

information for some items (e.g. items created as aliases to

other items). In such case, generated configuration files must

be edited manually.

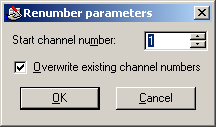

Assigning channel numbers

Newly added channels have the channel number cell empty

(undefined). Channel numbers can be added individually for

each channel or can be assigned for all channels using menu

Channels/Renumber channels. Renumbering can affect

only channels with undefined numbers or can update numbers of

all defined channels.

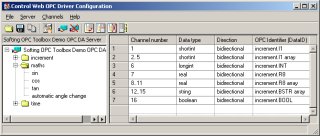

Renumber channels window Assigning channel numbers to arrays

Because items of OPC array are mapped to individual

channels, their numbers must be continuous sequence. This is

why only the first channel number has to be entered in the

configuration tools. Following array elements are numbered

sequentially.

Channel numbers must be unique, which is true also for all

elements of arrays. If there are for instance defined channels

number 1, 4 and 7, then to the elements of the array

containing three items can be assigned no lower numbers than

8, 9 and 10. Do not be confused by the error message

“Channel number redefined” — such

message can be caused by insufficient number of free channel

numbers for the whole array, even if the entered number (the

number of the first element) is not used.

The automatic channel numbering mechanism always assigns

unique numbers to single items as well as to arrays. If you

use automatic renumbering and there are some channels or

arrays with already assigned numbers, newly assigned numbers

for different channels and/or different arrays may by not be i

continuous sequence (elements of one array will be numbered

continuously, of course).

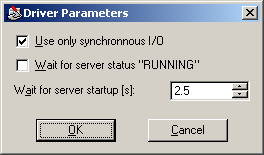

Channel array Driver parameters

It is possible to open a dialog window for specifying of

the driver parameters using menu File/Set driver

parameters... Parameters include

usage of synchronous communication, waiting for

“running” state and startup delay.

Driver parameters window Generation of configuration files

If all channels have assigned numbers, it is possible to

generate parameter (.PAR) and driver mapping (.DMF) files

using menu File/Write PAR and DMF files...

The menu command File/Copy channels to clipboard

can be used to put the text definition of channels (part of

the Control Web application source code) to

the Windows clipboard. The copied text can be pasted to the

text editor of the Control Web integrated

development environment and possibly modify channel names and

other attributes.

Loading of existing parameter file

Menu command File/Open existing PAR enables

opening of some existing parameter file to the configuration

tool. This command disconnects currently selected OPC server

(if one is selected) and clears all channels defined. Then the

server defined in the opened PAR file is created and the

channel list is filled by channels defined in the PAR

file.

Because the OPC server may not support all channels defined

within opened PAR file, the configuration tool checks if such

channels (OPC data identifiers) are available on the server.

It the OPC server does not provide some channel(s), the

configuration tool displays the corresponding line(s) with red

color and these item will not be included into newly generated

DMF and PAR files.

|