The S_MPI driver provides communication of Control Web application with SIMATIC S7 PLCs over the MPI or PROFIBUS

protocol.

Driver features

The driver enables connection of one or multiple SIMATIC

S7 PLC(s) to Control Web application. Supports communication with S7-200 and S7-300/400/M7/C7

series PLCs. Reads and writes data from/to D, V, M, A, E, T, Z,

Sareas. Enables manipulation with individual bits of the M

area.

Warning: The driver requires the Simens PRODAVE S7

product installed on the computer. List of sections: - Driver features

- The PRODAVE S7 software support

- How the driver works

- Driver parameters

- Driver channels

- Driver procedures

- Driver map file and data types

- Driver exceptions and their handling

- Error codes

- Example of driver usage

The PRODAVE S7 software support

Control Web MPI driver requires the Siemens

PRODAVE S7 (v.5.5 and higher) product is installed on the

computer. The PRODAVE is supplied in two versions. The cheaper

PRODAVE S7 mini enables data transfer to/from

S7-300/400/M7/C7 datablocks only. Only the Varea is

supported in the case of S7-200 PLC. The full version of

PRODAVE S7 supports also data transfer to/from M, A, E,

T, Zand Sareas. Appropriate hardware is also required

to communicate over the MPI interface. It is possible to use the

PCI plug-in board CP5611 or the PCMCIA adapter CP5511. It is also

possible to use external PC Adapter (MPI), which is connected to

the standard PC serial interface RS-232C. It is of course

necessary to install appropriate drivers for the used

hardware..

The Siemens PG/PC interface configuration

It is necessary to configure the PC/PC interface for the

driver to work properly. Configuration tools can be found in

the Windows Control Panel under the icon:

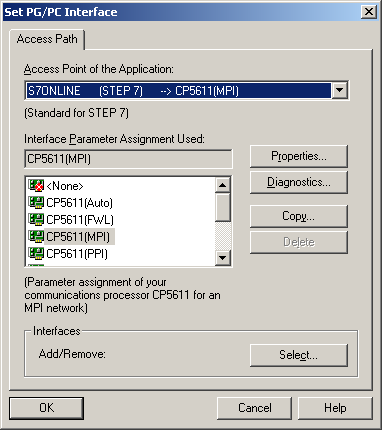

It is necessary to choose so-called Access Point first.

Choose the S7ONLINE from the combo-box:

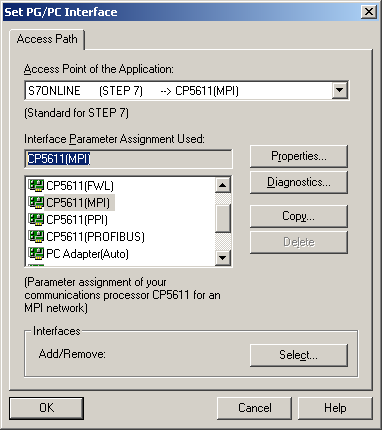

Then it is necessary to define other parameters. Select

communication hardware and MPI interface. The CP5611 card is

chosen as an example here:

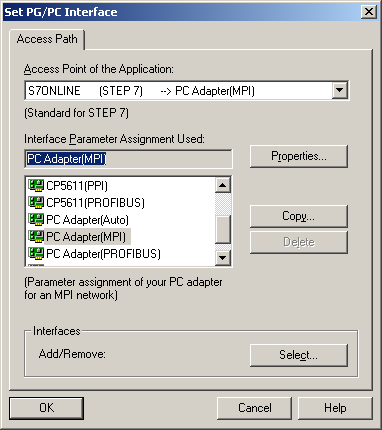

Another possibility is the PC Adapter (MPI):

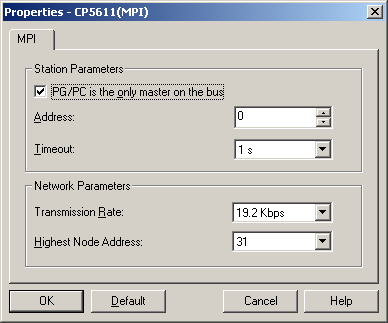

Clicking the Properties button opens dialog pox

for particular hardware. It is important to define

communication speed properly. Take care to define if the PC

(PG/PC) is the only master in the MPI network. If you use

S7-200, this option must be checked.

The S_MPI driver creates the 'ERROR.DAT' file in

the Control Web directory with error

messages. The PRODAVE S7 software creates another two

files 'ERROR.ENG' and 'ERROR.GER' with

error messages in English and German languages. The

'ERROR.DAT' file can be replaced by one of these

files, but it is necessary to keep the '.DAT'

extension.

How the driver works

It is possible to read and/or write data from/to data areas D,

V, M, A, E, T, Zand S. It is also possible to manipulate

with individual bits of the M area.

The driver automatically detects the version of PRODAVE

S7 installed on the particular computer and uses only the

functionality provided by the installed version. If the driver is

configured to use unsupported data areas, it will generate an

error during the application startup.

The driver interprets PLC'sdata elements as boolean or

numeric channels. Data element is usually a byte (in the D, V, M,

A, E and Sareas) or word (in the T and Zareas).

Numerical values can be of different types (int8,

uint8, int16, uint16,

int32, uint32, float32,

float32s), depending on the number of data elements

occupied. Also logical channels can be of different types (bits,

sbit, bool8) depending on the

interpretation (one bit or whole byte). If the whole byte is

interpreted as one logical value then zero value means false,

non-zero value means true. Driver data channels (number of

channels and their types) are configured in the driver parameter

file according to the user needs.

Driver parameters

The driver parameter file defines various communication

parameters and also individual channels. The whole parameter file

is divided into individual sections. Section name is delimited by

square brackets. Individual parameters within the section follows

the parameter_name = parameter_value convention. Every parameter

occupies exactly one line.

Connections definition — section

[Connection]

All devices (PLCs), with which the driver has to

communicate, are defined in this section. Every device has

assigned name, which identifies it in the [Channels]

section, and also device address and possibly another

parameters identifying the device are defined here. Number of

connections is limited to 32. Every connection is defined on

the separate line according to the following syntax:

[Connection]

<Id> = station:<N>, segment:<N>, rack:<N>, slot:<N>, cpu:<N>

<Id> = ...

...

Id - connection identifier, which

will be used in the [Channels] section. Id is a

character string of maximal length 32 character. N - numeric value. It can be written

in the decimal or hexadecimal notation (hexadecimal number

must begin with number and end with the character H, e.g.

0A1H).

The cpu parameter defines PLC series. The

S7-200 is identified by the number 200, Higher models

(S7-300/400/M7/C7) are identified by the number 300. It is

also possible to use short notation, where on the right side

of the equal sign are only numbers in the following orders:

station, segment, rack, slot, cpu.

Example of the [Connection] section

parameters:

[Connection]

CPU314 = station:3, segment:0, rack:0, slot:2, cpu:300

or

CPU314 = 3, 0, 0, 2, 300

Driver parameter definition — section [Settings]

This section contains parameters, which configures the

driver. Individual parameters and their possible values

are:

[Settings]

DeviceName = <Device>

ErrorFile = <File>

SwapBytes = true | false

MaxExceptions = <N>

FinalizeAfterEachBlock = false | true

Trace = none | log | xtrace | windows

| Device | string (S7ONLINE). | | File | string ('ERROR.DAT'). | | N | numeric value. It can be written in the decimal or

hexadecimal notation (hexadecimal number must begin with

number and end with the character H, e.g. 0A1H). |

Individual parameters description: | DeviceName | Name of hardware driver (Access Point) — typically S7ONLINE. | | ErrorFile | Error messages file name — e.g.

'ERROR.DAT'. This file must be in the

Control Web root directory. | | SwapBytes | flag which states whether swap byte

order is altered in the word. This flag is global for all blocks. If it

is set to false or is not stated, it is possible to set swap byte order

individually within the channels blocks. | | MaxExceptions | size of the queue for unprocessed

exceptions from the driver. The default setting is 4096. | | FinalizeAfterEachBlock | using this parameter it is

stated whether data will be transferred to the application after each

communication (the value of the parameter = true) or after

completion of the transfer of all blocks which are resolved within the

respective time step. The default value is false. | | Trace | switching of communication trace outputs.

If it is necessary to monitor the communication of the driver with the

device, it is possible to select by this parameter the target of trace

outputs. Possible values of the parameter are: | none | no trace outputs | | log | outputs are directed into Log window of the tab

Debug of the Control Websystem | | xtrace | outputs are directed into the file

'\XTRACE.TXT' | | windows | outputs are directed into the debug window of the Windows

system |

Warning: Trace outputs slow down the activity of the

application or they may lead to decreasing the space in the memory or on

the disk. Therefore, it is not recommended to use trace

outputs in the final application. |

Example of the [Settings] section:

[Settings]

DeviceName = S7ONLINE

ErrorFile = ERROR.DAT

SwapBytes = false

MaxExceptions = 1000

FinalizeAfterEachBlock = false

Trace = none

Channels definition — section

[Channels]

This section defines individual channels or group of

channels and their representation in the PLC'smemory.

Groups are defined in individual blocks. One block is defined

by the range of channel numbers, connection identifier, PLC

data area, data type and start and end addresses in the PLC

data area. It is possible to define parameter bidirect, which

eliminates collisions of bi-directional channels during

overlapping read and write operations — there are two independent channel blocks for

read and write created in the driver. Another optional

parameter defines byte swapping for types longer than 1 byte.

It is also possible to add a comment. Comments must be on

separate lines and must begin with semicolon.

One block represent maximal continuous data area

transferred during one communication transaction from the

communication point of view. However, the maximal size

transferred also depends on the used protocol and on the lower

layers. They can split the block to even smaller packets.

Every channel group (block) is described on one line.

Syntax for one block description is as follows. Optional

parameters are in square brackets.

[Channels]

Block = <From>,<To>,<Con>,<Area>,<Type>,<Adr>[,Bidirect] [,SwapBytes] [,Id:<Name>]

Block = ...

...

| From | Number of the first channel in block. | | To | Number of the last channel in block. | | Con | Connection identifier (see section [Connection]). | | Area | PLC data area code. Available codes are: | V | Memory ares V (variable memory). Available only

inS7-200. | | M | Memory area M (flag bytes). | | A | Binary outputs area. Also Oor Q symbols can

be used. | | E | Binary inputs area. Also I symbol can be

used. | | T | Timers area. | | Z | Counters area. Also C symbol can be

used. | | S | Special memory area S. Available only

inS7-200. |

| | Type | Area data type. Available types are: | bits | 8 boolean channels in one byte.

bits type always works with the whole byte

in PLC memory. The smallest amount of transferred data

is 1 byte. | | sbit | This type enables writing of individual bits in

the M area. It is more efficient to use bits

type it the case more than 8 bits are written. But the

whole byte is transferred during read operation

(similarly to bits type). | | bool8 | One boolean in one memory byte. Zero

means false, non-zero means true. | | uint8 | Unsigned 8-bit integer. | | int8 | Signed 8-bit integer. | | uint16 | Unsigned 16-bit integer. | | int16 | Signed 16-bit integer. | | uint32 | Unsigned 32-bit integer. | | int32 | Signed 32-bit integer. | | float32 | 32-bit IEEE-754 floating point number. | | float32s | 32-bit PLC SIMATIC S5 (format KG) floating point

number. |

| | Adr | Start address in the data area. Address are expressed

in bytes. Only T and Ztypes are expressed in words (2

bytes). | | Bidirect | This block will be both read and written. This

parameter is optional. | | SwapBytes | Bytes will be swapped in words. This parameter is

optional. | | Id | Name is block identifier. This name

can be used to dynamically change the block start address

during application runtime. The start address can be

performed using driver procedures SetBlockId

and SetBlockOffset. Identifier maximal length

is 32 characters. This parameter is optional. |

Example of the [Channels] section:

[Channels]

Block = 200, 299, CPU315, M, sbit, 50

Block = 300, 347, CPU314, A, bits, 124

Block = 500, 547, CPU314, A, bits, 124

Block = 1100, 1999, CPU315, D100, uint16, 50, Id:InD100

Block = 2100, 2999, CPU315, D100, uint16, 50, Id:OutD100

Block = 3000, 3009, CPU315, Z, 0

Block = 4000, 4009, CPU315, T, 0

Driver channels

The driver interprets various parts of PLC data areas as

numeric of boolean channels. Channels are defined in the section

[Channels] of the parameter file. However, some

channels with fixed numbers are predefined and cannot be used for

data transfer.

Driver reserved channels

The driver reserves channels with numbers from 1 to 99 for

diagnostic and maintenance purposes. Never use channels with

numbers lower than 100 in the data channels definition (in

section [Channels]).

channel No.1 - real input -

driver exception state channel No.2 - boolean output -

enables driver exception channel No.3 - real input -

number of handled exceptions channel No.4 - real input -

number of unhandled exceptions in the driver queue channel No.5 - real input -

address of device which caused exception channel No.6 - real input -

error code channel No.7 - string input -

error description channel No.8 - real input -

number of the first channel of block, which transfer caused

error channel No.9 - real input -

number of the last channel of block, which transfer caused

error channel No.10 - real input -

code of the area, which transfer caused error:

68 - area D 86 - area V 77 - area M 65 - area A 69 - area E 84 - area T 90 - area Z 83 - area S This is the ordinal number of particular

character. It is possible to use the function char

in the Control Web application to convert

the number to the character. channel No.11 - real input -

number of read error channel No.12 - boolean output

- zeros the read error counter channel No.13 - real input -

number of write error channel No.14 - boolean output

- zeros the write error counter channel No.15 - not used channel No.16 - real input -

device error code (see PRODAVE S7

documentation) channel No.17 - boolean output

- reinitializes the PRODAVE S7 software

layer channel No.18 - string input -

device error description (according to the

'ERROR.DAT' file).

Automatic type conversion

It is necessary to create also the '*.DMF' file

together with the parameter file to properly define channels

for the Control Web application. The DMF file

contains list od channels and their types — this definition enables syntax (proper channel

numbers) and semantic (proper channel types and directions)

checks during application compilation.

The driver does not require strict type matching between

parameter and DMF files. It is only recommended to assign

boolean type to the bits, sbit

or bool8 types. Another numeric types can be

combined. For instance it is possible to define all numeric

channels as real in the '*.DMF' file,

while they are of type int16 in the PLC.

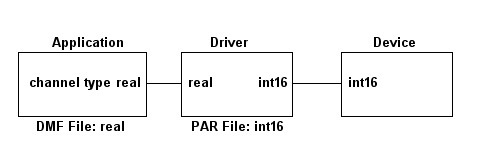

Example of the automatic type conversion between

real and int16 types Driver procedures

Driver

proceduresThe application may call for the driver certain

procedures using which it is possible to control the behavior of the

driver or to gain important information. This is done by means of the

system procedure: system.DriverQueryProc( DriverName : string; Param1 : any; &Param2 : any ) Parameters of the procedure have the following

meaning: | Parameter | Meaning |

|---|

| DriverName | symbolic name of the driver defined in the

application, | | Param1 | serves for typing of the command (name of the driver

procedure). | | Param2 | is used as a parameter of the procedure or the return value

of the procedure. |

DriverName and Param1 are typed as

text strings. Param2 is of various type according to the

meaning of the procedure. Some procedures serving for setting of

parameters may finish in error.

Overview and meaning of driver procedures (Param1 parameter)

- GetResult

-

Returns the result of the last called

driver procedure. The result is some of the error codes described in the

Chapter Error codes. This procedure should

be called after the calling of those procedures for which an error

occurred.

- GetVersion

-

Returns in Param2 the string

describing the driver name and its version.

- GetMajorVersion

-

Returns version higher word of

the product Control Web.

- GetMinorVersion

-

Returns version lower word of

the product Control Web.

- GetAPIMajorVersion

-

Returns version higher word

of the API product Control Web.

- GetAPIMinorVersion

-

Returns version lower word

of the API product Control Web.

- EnableException

-

By calling this procedure the

further driver exception is permitted.

- GetErrorCode

-

Returns the error number of the

just processed driver exception.

See chapter Error codes for

details.

- GetErrorString

-

Returns the error description of

the just processed driver exception.

- GetExcStatus

-

Returns the just processed driver

exception code.

See chapter Driver exceptions

and their handling for details.

- SetTraceOutput

-

Sets the target of trace outputs of the communication. The

parameter states the output target. | Value | Meaning |

|---|

| 0 | no trace outputs | | 1 | outputs are directed into the debug window of the Windows

system | | 2 | listings are directed into Log Windows of the tab

Debug outputs of the Control Websystem | | 3 | outputs are directed into the file

'\XTRACE.TXT' |

- SetBlockId

-

Sets the identifier of the current

block of channels for change of the address (offset) in the PLC memory.

The parameter is of the type string and the block

identifier is transferred in it (maximally 32 characters). This

identifier must be identical with the identifier in the definition of

blocks in the parameter file.

- SetBlockOffset

-

Sets the address (offset) of the

beginning of the block in the PLC memory. The block is determined by its

identifier in the parameter file and is selected by calling of the

procedure SetBlockId. The parameter can be of any numeric

type. Warning: The range of the parameter is not

monitored.

Driver map file and data types

DMF file contains types and directions for individual channels.

because the driver has a fixed set of maintenance channels and

also a variable set of data channels, the DMF file should always

contain part describing fixed set of channels and part describing

actually defined data channels corresponding to channels defined

in the [Channels] section in the parameter file.

| Data type |

Channel type |

Description |

| uint32 |

number |

32-bit unsigned value - 4 bytes |

| int32 |

number |

32-bit signed value - 4 bytes |

| float32 |

number |

32-bit real value - 4 bytes |

| float32s |

number |

32-bit real value - 4 bytes |

| |

| uint16 |

number |

16bit unsigned value - 2 bytes |

| int16 |

number |

16bit signed value - 2 bytes |

| |

| uint8 |

number |

8bit unsigned value - 1 byte |

| int8 |

number |

8bit signed value - 1 byte |

| bool8 |

boolean |

1 boolean value - 1 byte |

| bits |

boolean |

1-bit value - 8 in 1 byte |

| |

| sbit |

boolean |

1-bit value accessible for write |

Driver data types

Driver exceptions and their handling

The exception is raised when communication error appears. This

exception can be handled by any virtual instrument within the

application. The particular virtual instrument must define the

driver_exception parameter with the driver symbolic

name. In this case the instrument is activated when the exception

appears. It is necessary to write the true value to

the channel No. 2 or to invoke EnableException driver

procedure. This enables generation of next exception (if any). It

is possible to read channel No. 1 to obtain the exception state.

Keep on mind the send_same_data parameter must be set

to true if the instrument writes channel No. 2 (else

the next write of the same value will be discarded). If the

application does not handle exceptions, they are added to the

queue. Maximal queue length is defined by the parameter MaxExceptions

in the [Settings] section.

Exception status codes

0 - No exception. 1 - Exception signals data read error. Error

code and description can be obtained by GetErrorCode

driver procedure call or from the channel No. 6. 2 - Exception signals data write error.

Error code and description can be obtained by GetErrorCode

driver procedure call or from the channel No. 6. 3 - Data in device changed. This is the way

to signal data changed in the case of asynchronous

communication or if the driver works in the slave

mode. 4 - Driver procedure error. Because some

procedures can take rather long time to execute, they are

executed in the parallel thread not to block the

application. If the procedure ends with error, this

exception signals it.

Error codes

The driver generates several error codes. The code of actual

error can be read from the channel No. 6. Error code, together

with the error description, can be also obtained by calling GetErrorCode

and GetErrorString driver procedures. It the error

condition occurs then an error message is also written to Log

Window of the Control Web.

0 - success 1 - timeout error 2 - invalid value 3 - non-existing channel

1000 - internal error 1001 - checksum error 1002 - input communication buffer full 1003 - invalid device address 1004 - invalid function code 1005 - received data has invalid length 1006 - acknowledge error 1007 - invalid response 1020 - invalid procedure parameter 1021 - no data available 1022 - unknown driver procedure 1023 - unknown block identifier 1024 - invalid address (offset) within

block 1025 - device unplugged 1026 - data element read-only

Example of driver usage

There are several examples of the driver usage in the package

installation. These examples can be found in the

'EXAMPLES\S_MPI' directory. Examples also contain

'*.DMF' and '*.PAR' files. It is necessary

to modify these files according to actual device

configuration.

|