|

Technologies used in industrial automation are therefore

traditional, tested by years and sometimes even decades of practical

usage. People investing in their hobby always want the best, they are

actively interested in the state-of-the-art technologies and very

carefuly consider the price-performance ratio. But at work they

generally use assigned tools and the interest in utilizing the most

sophisticated resources is not as essential. Fortunately even in this

field isn't everything black or white. There are a lot of active and

creative people, who are continuously in the quest of finding their

way onwards.

Still relatively recently programs running in text mode were

commonly used for industrial process visualisation. These programs

were quickly displaying column indicators, pipe installations and open

or closed valves with the aid of semigraphics characters. That was the

time when we were writing letters and e-mails in Windows GUI programs

already for many years. But where is the semigraphics now? Its usage

could have been justified only by technical incufficiency of computers

and the existence of text-based terminals. And those who said that it

would always be enough, because semigraphics was utterly sufficient,

were luckily not right (I still recall well those "productive"

discussions). Today's standard in technological process visualisation

is the usage of 2D vector graphics. And again it is certain that it

will not last forever.

2D vector and bitmap graphics

In the following text we are going to deal with graphics

technologies available in Microsoft Windows environment. The

displaying of 2D graphics is done with GDI system (Graphics Device

Interface). It is one of three main and oldest parts of the

Windows system. Modules KERNEL, USER and GDI are the base of

Windows since version 1.0, 2D graphics has therefore always been a

solid part of operating system kernel services.

System GDI is being improved and widened with every new

generation of operating system, but still maintains continuity

with original, today quite aged, conception. Present-day

requirement on 2D visualisation presume the existence of support

for animation, transparency, gradient filling and picture

transformation. That is why there is usually built a more complex

and sophisticated drawing system upon the GDI. Today, even the

Windows system is equipped with additional technologies for image

creation. There is a GDI+ system, whose API consists of a C++

class hierarchy, and a very powerful Direct3D system. GDI+ brings

many new possibilities in 2D vector graphics (for example gradient

brushes, matrix transformations of coordinate system or color

space, alpha blending, etc.), manipulation of bitmaps and also in

typography. It is hard to guess future support of this interface

at this moment, it may be a dead-end branch. Direct3D is, unlike

GDI+, built upon the stadndard of COM interface. This 3D rendering

system could be (like OpenGL) used for vector 2D graphics as

well.

As stated before, GDI services are a part of operating system

kernel (but it is quite hard to trace what is done on the side of

the client and what is done inside the kernel). Plenty of calling

these services from application to system kernel impose a context

switching overhead. This overhead is usually longer than the

actual realization of graphical primitive by an accelerator.

Therefore even a high-end graphics card is unable to help better

graphics performance. Accumulation of function calls and their

consecutive massive delivery to system during image drawing

completion helps solving these problems. This is the way 2D

graphics is dealt with in vector drawing system in Control Web

environment.

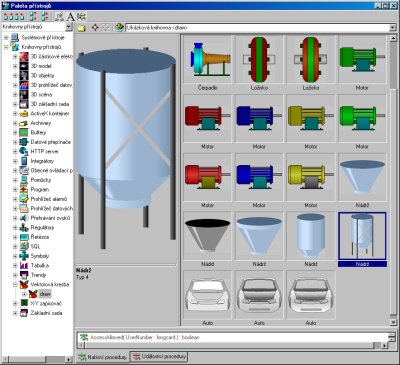

Fig.1: Own drawings can be in Control Web environment saved

to libraries for later application Next problem is disturbing flickering during screen refresh. It

is caused by rendering system directly modifying graphics card

memory, which is used for image gereration on monitor. System

Control Web copes with it identically for the whole 2D graphics

included in the application. Each panel can be with setting the

property mode = off_screen ensured that it will be

drawn to invisible memory and the result will be transfered to

visible part of the memory all at once after finishing the image.

This operation is always supported in hardware of the graphics

card and is very quick. The resultant image is clear without any

flickering.

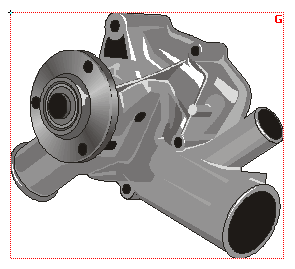

Fig.2: An example of 2D vector image in Control Web

environment. If the resultant image is treated this way, the way it was

created does not matter any more (it is the same for both 2D and

3D graphics). Modern rendering systems for image generation use

vector processor with floating point arithmetics and a rasterizer

for final bitmap image generation. That way works for example

Macromedia Flash, Adobe PDF and Adobe SVG Viewer (Scalable Vector

Graphics - W3C XML standard for portable graphics).

Future generation of Windows system called Longhorn is going to

operate on a similar basis. New interface Avalon - XAML

(eXtensible Application Markup Language) will give an oportunity

to describe graphics user interface in a declarative way. Even

though we use one of the modern technologies for image creation,

we cannot avoid GDI at least for context manipulation and final

image placement to destination window. GDI system is going to

accompany us still for a very long time and is certainly going to

be a part of the new OS Windows Longhorn. But we are more

interested in what we can use for the benefit of our applications

right now. Let's proceed to the most interesting part -

interactive 3D graphics.

3D graphics

What makes a 3D rendering system so interesting? If we pass

over unbeatably visually impressive images, then it is certainly

the capabilities of today's graphics accelerators. We have a

3D accelerator in every contemporary computer and not using it

would be a big waste. It would be like insisting on

black-and-white imagery in the age of color monitors. The

principle of image creation is similar to the one described in

previous chapter. The base of accelerator's horsepower is

pipelining and parallelism. For example the

today's accelerator GeForce 6800 with more than 220 million

transistors has 6 parallel vector processors and 16 parallel pixel

processors in hardware (during writing to z-buffer and stencil

buffer it has even 32 parallel pixel channels - and that is a big

benefit for Control Web and other modern drawing systems). The product

are dozens of gigabytes data bandwidth per second and the ability

to render hundreds of millions of shaded triangles per second. Now

admit - could you leave this potential lie idle?

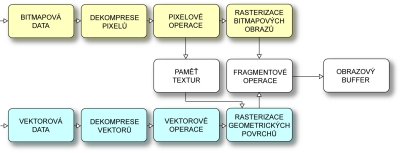

Fig.3: OpenGL image creation pipeline

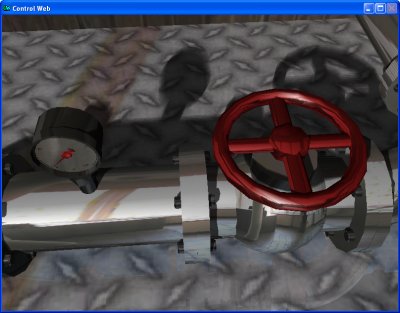

Fig.4: Image with mirroring, specular reflections and

volume shadows rendered by Control Web with the aid of multipass

rendering techniques A short glance at history

The 3D computer graphics field is coming through a rapid

technological development. The driving force ot this progress

are indisputably computer games. Thanks to the size of the

computer games market, still more powerful 3D accelerators are

being developed. The usual performance is about hundreds of

millions of triangles per second and tens of gigapixels per

second data flow

The milestone in 3D graphics development was the year 1992,

when Silicon Graphics (SGI) introduced their

Reality Engine. This graphics

accelerator contained 8 graphics processors with hardware

transform, lighting and rasterization including texture

mapping. It cost about million dollars and the proportions

were like a home refrigerator. Today, even cheap graphics

cards for less than 50 dollars considerably overpower its, at

that time revolutionary, performance. During 10 years the

price of a comparable graphics accelerator dropped about 20000

times!

The era of cheap 3D graphics accelerators was started by

3Dfx in 1996 with their card Voodoo 1. This successful adapter

convinced everyone about the usefulness of hardware support of

3D graphics. By now an accelerator became an implicit part of

every home PC, like a mouse or a pair of reproductors. And the

near future - hardrware support of 3D graphics is inevitably

coming also to handheld computers and mobile phones.

As mentioned before, we can say from the

user's perspective with a little bit of pragmatism that we do

not care about the principle of image generation. The only thing

we are concerned about is that the picture looks good and the

rendering does not take too long. We stick to a rule, that what

cannot be rendered in realtime, should not be rendered at all. And

if we do not want to deal with specific problems of 3D graphics,

we do not have to. While building an application in Control Web system

we often do not have to bother with creating 3D scene, it is

sufficient to make use of only a part of 3D drawing system for

common 2D visualisation.

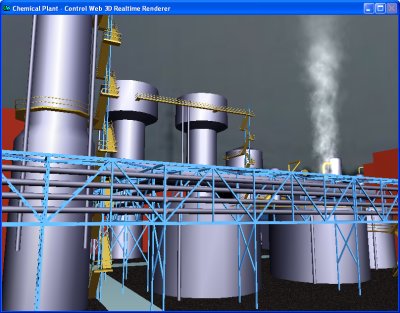

Fig.5: Visualisation of industrial technology rendered

in one pass without additional effects Even then brings us 3D rendering system in Control Web

environment great benefits:

we use raw horsepower of 3D accelerator to carry over

part of the burden from CPU to parallel GPU of graphics

card application gets perfect appearance of lit and

three-dimensionaly modelled image application program is faster and more precise in

realtime - rendering server is in its own thread and his clients

running in realtime do not care about graphics at all

Fig.6: With one pass rendering we use raw horsepower of

graphics card and save the power of CPU If we ever want to use more of this graphics

technology, we have at hand:

editing the 3D scene "in-place" on the desktop of

integrated development environment free camera movement in the scene including position and

angle interpolation both while editing and at application

run a number of prepared 3D objects for quick and easy-going

visualisation building tree system of transformation and animation and the

possibility of full program control of the scene particle system for realistic and dynamic displaying of

three-dimensional effects with objects prepared before (fire,

smoke, sparks, etc.) editable materials with an option of transparency,

texturing, etc. import of 3D models (*.obj, *.3ds) from various 3D

modelling programs light source visualisation and simulation of reflections

and light scattering in camera optics

Fig.7: Volume shadows concurently with light source

visualisation mirror surfaces planar shadows volume dynamic shadows with efficient and robust

algorithm and much more ...

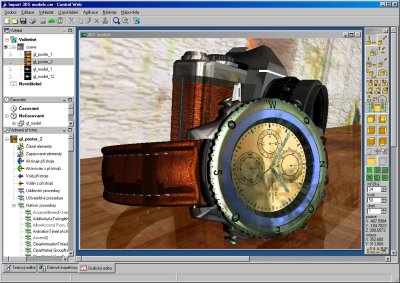

Fig.8: In-place 3D editor of Control Web development

environment provides free movement in the scene being created

including drawing all effects These possibilities show technological advancement of rendering

system and of course we do not have to use them always. But it is

convenient to have them at hand.

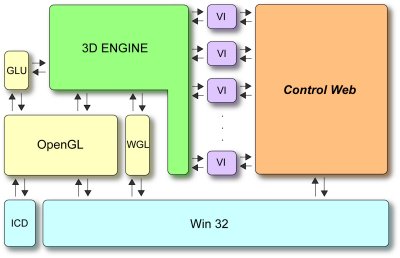

Fig.9:3D rendering machine architecture in Control Web

system The information about 3D rendering system architecture and his

placement in Control Web environment structures is important as well.

As we can see in Fig.8 the rendering system grants his services

only to appropriate virtual machines, not to the Control Web system

kernel. Rendering system is therefore dynamicaly loaded with the

first virtual machine that needs it. Thus we do not have to be

worried that in soft PLC applications without visualisation or in

applications with 2D visualisation would the 3D rendering system

components interfere, block memory in virtual memory space and

delay the application start.

3D rendering in realtime

It is good to take a think why to be interested in 3D

graphics in industrial automation(if we went without it for so

long :-)). There is perhaps only one argument against it

- the building of visualisation is a little harder. This is true

to some extent, but the easiness of 3D visualisation creation

was the main design of 3D graphics environment in Control Web

system. In many cases we can create 3D scenes even without a

deeper understanding of the topic and without the need of

difficult external 3D model creation. On the other side there

are many arguments for the benefit of 3D

visualisation:

Appearance — now it is the best available

visualisation technology. 3D rendering is used for film making,

in computer games, for model visualisation in science and

research, in CAD programs, for data presentation, etc. Therefore

it is more than time to introduce it to industrial

visualisation. Performance — 3D accelerator is a common

part of every today's computer and it would be a waste not

using this potential. Architecture — client-server rendering

system, maximum of the rendering is handled outside the

operating system kernel. That brings better optimisation

opportunities and smoother realtime run. Price — we use the same computer and

create the applications the same way as before with 2D

visualisations. So we get higher quality without the need to pay

too much money.

Fig.10: Control Web system logo rendered in realtime

directly by Control Web system Not using a 3D graphics system for visualisation would be, in

the case it is present on the computer in the form of a graphics

card and installed drivers (and it mostly is there), like driving

a car only with first gear

The domain of industrial automation is traditionally a very

conservative field, which however is not one of the technological

pioneers in the IT field. But in Control Web system in 3D graphics we can

use not only the great power of modern accelerators, but also thanks

to the implementation of the latest software technologies and

algorithms for three-dimensional visualisation in realtime we can

create fast and visually impressive graphics presentations. We do not

have to mimic the three-dimensional visualisation with only the aid of

bitmaps prepared in advance any more. We can have real

three-dimensional visualisation in realtime!

Roman Cagaš, rc@mii.cz

|