|

Contents of section: - Connecting multiple DataLab IO

devices to single computer

- Driver exceptions

- Driver status channel

- Driver parameter file

- Section [device]

- Module sections [module_x]

- Channels and modes of individual module types

- Digital input modules DI1 and DI2

- Digital counter module CNT1

- Incremental counter module CNT2

- Digital output modules DO1, DO2 and DO3

- Analog input module AI1

- Analog input module AI2

- Analog input module AI3

- Analog output module AO1

- Combined analog input and digital input/output module

AD1

- Combined analog input/output and digital input/output

module AD2

- Combined analog input/output module AIO1

- Module for Resistive Temperature Detectors RTD1

- Mode and control channel usage

- Driver-specific error codes

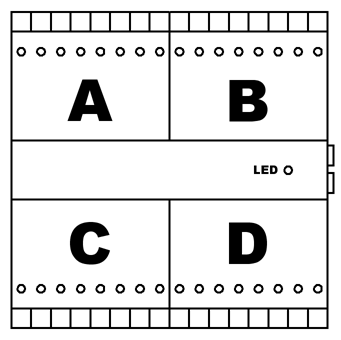

- Module positions and device slots

- Driver configuration in the Control Web

development environment

- DataLab IO system driver

- Operating system support

- History of function enhancements

Channel data types (either numbers representing analog values or

two-state logical values) and directions (either inputs or outputs)

are defined by the module types plugged to individual slots of the

particular unit. It is necessary to define used module types in the

driver parameter file to enable application

development. The driver creates a set of channels of appropriate type

and direction for each module according to module type.

Channel numbers associated to used modules are freely selectable,

but always must create a continuous range. So it is possible to choose

only the number of the first channel, other channels are numbered

automatically up to the total number of channels available in the

module. Channel numbers assigned to individual modules cannot

overlap.

If the particular module provides both input and output channels,

channel numbers can be assigned independently for both channel groups

—number of the first input channel is defined

independently on the number of the first output channel.

If the module type plugged to device slot does not correspond to

the module type define in the parameter file, the driver detects it

and any attempt to read or write to channel of the particular module

causes error (see chapter Driver specific error

codes).

No other configuration (e.g. unit addressing, communication speed,

parity, handshake, stop-bits settings etc.) is required due to the USB

interface used in the DataLab IO units. The

system works in the pure Plug-and-Play manner.

The DataLab IO driver for Control Web relies on the DataLab IO system

driver (see chapter DataLab IO system driver). It is not possible to

communicate with the device over USB without properly installed system

driver.

Connecting multiple DataLab IO

devices to single computer

It is possible to connect multiple DataLab IO devices to single computer, be it directly to

USB ports available on the computer I/O panel or through the

USB hub. The operating system assigns unique name to every

connected USB device. The name is rather complex string derived

from the device driver GUID, USB hub identifiers, USB port number

on the particular hub etc. Simply put, these identifiers are

intended for distinguishing USB devices within operating system,

not to be used by computer users.

But if the application communicates with multiple

DataLab IO devices, it is necessary to

distinguish them—the concrete signal wired

to concrete terminal port of the concrete module must be properly

identified in the application. The device serial number is used

identify devices. The serial number is always printed on the label

on device case and is necessary to write it as parameter id

of section [device] in driver

parameter file. It is necessary to use one driver instance

for every DataLab IO unit. One driver

instance (with corresponding one parameter file) cannot handle

multiple units at once.

Warning: It is necessary to define the id

parameter not only when single application uses multiple devices,

but always when multiple DataLab IO

devices are connected to one computer. If the id

parameter is not defined, the driver uses the first device it

finds. Sometimes it can be necessary to obtain device identifier in

running application. The driver offers special input channel, from

which the device identifier can be read (its number is defined by

the parameter id_channel of section [device]

in the parameter file).

Driver exceptions

The driver generates exceptions always when its state changes.

The application (the virtual instrument within application) can

handle these exceptions (virtual instrument is activated when the

driver exception occurs if its parameter driver_exception

contains particular driver name). The exception handling procedure

can read the driver status channel to determine device state. An

example of the indicator instrument, which handles

DataLab IO driver exception and switches

on or off according to the device state is in the chapter Driver status channel.

Driver status channel

The status channel (its number is defined by the parameter

status_channel of section [device] in

the parameter file) provides the

DataLab IO device status information.

Currently only one bit number 0 is defined—it represents the “connected” status (that

means if the device is connected to the USB port and properly

powered). If the DataLab IO device is

unplugged (or without power in the case of self-powered devices),

the status channel is the only channel which can be read without

error. An attempt to read any other channel will generate error

1.

Status channel value should be interpreted as bit mask. It is

always necessary to check only the particular bit of interest.

Undocumented bits represents other states and their meaning can

change in different driver versions. It is possible to use

function bitget or operator and to

extracting just one bit from the number.

The following example demonstrates how to read DataLab IO “connected” state and how this state is

represented by indicator instrument. This example

assumes that there is a parameter status_channel = 99

in the [device] section in parameter file.

driver

datalab : 'dldrv.dll', 'DataLab USB test Analog In.dmf', 'DataLab USB test Analog In.par';

end_driver;

data

channel {driver = datalab; direction = input};

...

dlStatus : longcard {driver_index = 99};

end_channel;

...

end_data;

instrument

indicator ConnectionStatus;

driver_exception = datalab;

...

procedure OnActivate( ByTimer, ByInstrument, ByDriver, ByData : boolean );

begin

if ByDriver then

(* mask bit 0 by logical and with mask 1 *)

SetValue( dlStatus & 1 <> 0 );

(* it is possible get the bit using bitget function, the second parameter is bit index, not mask

SetValue( bitget( dlStatus, 0 ) <> 0 );

*)

end;

end_procedure;

...

end_indicator;

...

end_instrument;

Driver parameter file

Driver parameter file is an ordinary text file and can be

edited by any text editor (e.g. Control Web

Editor or Notepad). It has very simple

structure following '.INI' file conventions.

Section [device]

If there are multiple DataLab IO

units connected to one computer, it is necessary to specify

for which unit is the particular parameter file intended. The

parameter id of section [device]

defines the particular unit. Parameter value is a number or

list of numbers separated by commas. If the parameter is

present, the driver instance (with this parameter file) will

work only with the DataLab IO of the

serial number defined as id. The syntax of

parameter is id = number,number,..,number. If

there is only one device connected to the computer, this

parameter is optional and can be omitted with the whole [device]

section (if no other parameter of [device]

section is used, of course).

Hint: The number list can be used when the DataLab IO device should be replaced by another

device without stopping of the application and editing the

parameter file. The list then should contain the serial

numbers of both primary and the backup devices. The number of

devices in the list is not limited. If the status channel is required by the application, its

number must be defined by the parameter status_channel

in the [device] section. If the parameter file

defines this channel, it is necessary to define this number in

'.DMF' file as input channel of type longcard.

The status channel is described in the Driver status channel chapter.

Also the channel returning DataLab IO identifier number can be defined in the

[device] section. The identifier channel number

must be defined by the parameter id_channel. If

the parameter file defines this channel, it is necessary to

define this number in '.DMF' file as input channel

of type longcard.

It is also possible to define logical parameter reset_outputs

in the [device] section. If the parameter is true

(reset_outputs = true), all output

channels are reset to their initial state (the sate in which

channels are when the device is powered on) when the

application is terminated or when the host PC (or connection

to host PC) fails.

Module sections [module_x]

Every I/O module, plugged into the device,

must have a section in the parameter file named according to

the device slot (see chapter Module

positions and device slots). Sections names are in

square brackets : [module_a] to [module_d].

There are two mandatory parameters in each section: module_type

and first_channel. Other parameters (control_channel

and mode) are optional.

module_type defines module type:

DI1, DI2—8 logical inputs module. Both modules are

compatible from the software point of view so both

identifiers can be used. The drive also accepts the L

and H variants of module identifiers (DI1L,

DI1H, etc.), but their usage is not

recommended. DO1, DO2, DO3—8 logical outputs module. All modules are

compatible from the software point of view so any

identifier can be used. AI1—8 16-bit

analog inputs module. The AI1 module is discontinued and

the driver supports it only to maintain backward

compatibility. AI2—8 16-bit

analog inputs module. The AI2 module replaced the AI1

module. Although it also provides 8 16-bit inputs, the

new module is faster and has better capabilities (e.g.

the input range can be defined independently for each

channel) so it is different module from the driver point

of view. AI3—enhanced

AI2 module with 8 16-bit analog inputs. The analog part

of this module is optimized compared to AI2 module, so

the AI3 module provides lower noise and better

precision. Number of input ranges was extended from 4

bipolar modes of AI2 module to 7 bipolar and 7 unipolar

ranges. AO1—8 12-bit

analog outputs module. AD1—module

combines 4 16-bit analog inputs (with input ranges

equivalent to the AI3 module) with 4 digital

inputs/outputs. The digital channel direction as well as

the input resistance can be chosen by the jumpers on the

module board. AD2—module

combines 4 16-bit analog inputs (with input ranges

equivalent to the AI3 module), two analog outputs with

8-bits resolution and 2 digital inputs/outputs. The

digital channel direction as well as the input

resistance can be chosen by the jumpers on the module

board. CNT1—4

counter inputs module. CNT2—1

incremental counter module. RTD1—module

contains 4 inputs for Resistive Temperature Detectors.

It is possible to connect various Pt100, Pt1000 and

Ni1000 RTDs with different Temperature Coefficient of

Resistance (TCR). first_input_channel and first_output_channel

define number of the first channel of the respective

direction assigned to the module. The following channels are

numbered with increasing numbers up to maximal number of

channels provided by the particular module. It is possible

to use keyword first_channel instead of first_input_channel

or first_output_channel providing the

particular module has channels of one direction

only. control_channel defines number of the

module control channel (control channel functionality

depends on the module type). mode defines module working mode. The

meaning of the mode is different for various modules and

mode can be meaningless for some modules. Some modules

enable definition of mode independently for each channel

using keywords mode1, mode2,

etc. unit defines the representation of data

read from or written to particular module channels. Unit has

meaning only for analog modules, digital modules use simple

boolean values or unit-less count. Default unit is ADU

(Analog/Digital Unit), which represents native counts of

the A/D or D/A converter used in the particular module.

But module can also use physical units: Unit can be defined for all channels of the module

or independently for each channel using the keywords unit1,

unit2 etc. Hint: Unit definition for the

particular channel has precedence over the definition for

the whole module. If for instance the all channels of the

AO1 module are configured as voltage output and only the

first two channel are configured as current outputs, units

can be defined as follows: module_type = AO1

unit = V

unit1 = mA

unit2 = mA

DataLab IO1 has only one module

slot, which corresponds to position A. The parameter file for

DataLab IO1 should contain only one

module section [module_a].

Parameter file example:

[device]

id = 1234567

status_channel = 1

id_channel = 2

reset_outputs = true

[module_a]

module_type = DI1

first_channel = 100

mode1 = AC

mode2 = AC

[module_b]

module_type = DO2

first_channel = 108

control_channel = 120

[module_c]

module_type = AO1

first_channel = 200

unit = V

unit1 = A

unit2 = A

unit3 = A

unit4 = A

[module_d]

module_type = CNT1

first_input_channel = 300

first_output_channel = 310

control_channel = 320

mode1 = enable

mode2 = enable

mode3 = enable

mode4 = enable

Channels and modes of individual module types

Every module (depending on its module type) provides channels

for reading or writing of values. Some module types offer control

channel and/or mode. Channel types, directions, control channel

functions and modes for various module types are as follows:

Digital input modules DI1 and DI2

Module type designation in parameter file: DI1

or DI2. Data channels: 8 input channels of boolean

type. Control channel: bidirectional channel of shortcard

type:

Control channel provides values of all 8 inputs

as one number when read—every

input defines one bit in the read number. Writing to control channel defines mode for

individual inputs (see mode description). Mode: digital inputs can work with both positive and

negative signal polarity, so they are capable to detect not

only DC but also AC signals. If the input is configured to

detect DC signal, its logical value represents current level

of input voltage. But the logical value determination is

more complex in the AC mode:

Inputs are sampled at 1 kHz. If the voltage of any polarity occurs on the

terminal connector, the logical 1 (true) value is

returned from the time of the first sample, which

detects it. This means logical 0 (false) can be read up

to 1 ms from the time of the voltage

occurrence. If the voltage disappears from the terminal

connector, logical 1 (true) is read for the following

10 ms. When no one sample indicates voltage on the

input for 10 ms, the read value becomes logical 0

(false) again. The 10 ms delay corresponds to one

half-wave of 50 Hz AC signal, which means zero

crossings of the 50 Hz or 60 Hz signal do not

cause switch to 0. The sampling mode can be defined individually for

each input. Numerical value of the mode parameter (or

control channel write anytime at application runtime)

corresponds to the bit mask created from 0s and

1s for each input channel. If the particular bit is 1

then the input will work in AC mode, 0 means the DC mode

will be used. For instance the value 0 means all inputs will

work in DC mode, 255 (or 0FFH) means all inputs will work in

AC mode and 15 (or 0FH) sets channels 0 to 3 to AC mode and

channels 4 to 7 to DC mode. Mode can be also defined

by keywords DC and AC. Mode for

each channel must be defined individually in such case.

Because the DC mode is default, only channels which should

work in AC mode must be mentioned, for instance: mode1 = AC

mode5 = AC If the mode is not defined, the 0 (all inputs in DC

mode) is used by default.

Digital counter module CNT1

The module contains 4 counters with 24 bit range

(numeric range of every counter is 0 to

16,777,215). First two counters have more

configuration options compared to the second pair of

counters (last two counters are limited to simple counting

with the possibility to preset their value). Counter modes

(e.g. counting enabled/disabled, logical levels etc.) are

defined by setting module mode or by writing to module

configuration channel.

Module type designation in parameter file: CNT1. Output channels: 7 channels of longcard

type: No. 0—Preset0:

sets first counter value. Write to PresetX channel

overwrites the value of counter X. The counter then

continues incrementing the written value. Writing value 0 to

channel PresetX zeros the counter. It is also

possible to automatically zero counter upon its read (see

the description of counter modes). No. 1—Preset1: sets second counter

value. No. 2—Preset2:

sets third counter value. No. 3—Preset3: sets fourth counter

value. No. 4—Compare0: first counter compare

value. Surpassing of the CompareX value can,

depending on the counter mode, cause setting of the counter

X alarm output. No. 5—Compare1: second counter compare

value. No. 6—Config:

counter configuration. Values written to this channel are

described later. Input channels: 4 channels of longcard

type. No. 0—Counter0:

first counter value. Reading of the CounterX

channel returns current value of counter X. Read operation

can, depending on the counter mode, zero the counter

X. No. 1—Counter1:

second counter value. No. 2—Counter2: third counter value.

No. 3—Counter3:

fourth counter value. Control channel: output channel of longcard

type is identical to output channel No. 6: Config.

Mode: numeric value of the mode parameter is the same

as the value written to the Config or control

channel. Mode can be also defined as a list of keywords for

individual channels as described later.

Functionality of the first two counters (counters

number 0 and 1) can be more complex:

When the counter X exceed the value written to the

CompareX channel, the alarm output can be set.

Alarm output logic (if active low or high) can be defined in

the counter X configuration. Counting can be enabled/disabled by the external

input (gate). Gate logic (if active low or high) can be

defined in the counter X configuration. The inputs of

counters 2 and 3 are used as gate inputs (counter 0 is

enabled by the counter 2 input, counter 1 is enabled by the

counter 3 input).

Counter configuration can be written to the output channel

No. 6 Config, to the control channel (control_channel)

or can be defined as the module mode parameter.

Configuration value is 4B long unsigned integer. Every byte

contains configuration of one counter, the less significant

byte contains configuration of counter 0, the most significant

byte contains configuration of counter 3. Every byte meaning

is defined by the bitmask according to the following

table:

| Bit |

Counter 0 |

Counter 1 |

Counter 2 |

Counter 3 |

Meaning |

| 0 |

• |

• |

• |

• |

Counting enabled |

| 1 |

• |

• |

• |

• |

Counting of falling edges |

| 2 |

• |

• |

• |

• |

Zero counter upon read |

| 3 |

• |

• |

× |

× |

Test the gate input |

| 4 |

• |

• |

× |

× |

Set the alarm output |

| 5 |

• |

• |

× |

× |

Gate input is inverted (active low) |

| 6 |

• |

• |

× |

× |

Alarm output is inverted (active low) |

| 7 |

× |

× |

× |

× |

Reserved, must be 0 |

Individual counter configuration Mode can be defined also for every channel

individually:

mode1 = 1001B

mode2 = 1011B

mode3 = 101B

mode4 = 101B

Alternative way to define mode is using a list of

keywords:

enable—Counting

enabled falling_edge—Counting of falling edges reset_on_read—Zero counter upon read test_gate—Test

the gate input set_alarm—Set

the alarm output gate_inverted—Gate input is inverted (active low) alarm_inverted—Alarm output is inverted (active low)

Modes from the previous example can be defined as

follows:

mode1 = enable, test_gate

mode2 = enable, falling_edge, test_gate

mode3 = enable, reset_on_read

mode4 = enable, reset_on_read

Incremental counter module CNT2

The module contains 1 incremental counter 1 with

32-bit range (numerical range is from

-2,147,483,648 to

2,147,483,647). The counter is able to decode

quadrature modulation from position/angle sensors as well as

to work in up/down and step/direction modes. The counter is

also capable to preset counter value and capture value

according to logical inputs and to signal alarm outputs if

the counter value underflows low limit or overflows high

limit.

Module type designation in parameter file: CNT2. Output channels: 5 channels of longint

type: No. 0 – CounterPreset: sets counter

value. This value is used not only as new counter value

(counter then counts from this value), but it is also stores

to separate register and it will be used for overwriting of

counter value when the external input preset is

signaled (module input and output signals are described in

the DataLab IO device

documentation). No. 1 – CapturePreset: sets

capture register value. Current counter value is copied into

capture register when the external input capture is

signaled (module input and output signals are described in

the DataLab IO device

documentation). Writing to this channel can be used e.g. to

zero this register. No. 2 – CompareLo:

counter low compare value. If the current counter value is

less than this value then the alarm_lo logical

output will be signaled (module input and output signals are

described in the DataLab IO device

documentation). No. 3 – CompareHi: counter

high compare value. If the current counter value is greater

than this value then the alarm_hi logical output

will be signaled (module input and output signals are

described in the DataLab IO device

documentation). No. 4 – Config: counter

configuration. Values written to this channel are described

later. Input channels: 2 channels of longint

type: No. 0 – Counter: current counter

value. No. 1 – Capture: capture register

value. Either the value written to channel

CapturePreset (if no capture input signal

was detected between writing to CapturePreset an

reading of Capture) or the counter value in the

time of the capture input signaling is returned

through this channel. Control channel: output channel of longint

type is identical to output channel No. 4:

Config. Mode: numeric value of the mode parameter is the same

as the value written to the Config or control

channel.

Counter configuration can be written to the output channel

No. 4 Config, to the control channel (control_channel)

or can be defined as the module mode parameter.

Configuration value is 32-bit integer number. Individual bit

meaning is defined in the following table:

| Bit |

Meaning |

| 0 |

alarm_lo output enabled (when counter

underflows CompareLo value) |

| 1 |

alarm_hi output enabled (when counter

overflows CompareHi value) |

| 2 |

preset input enabled |

| 3 |

capture input enabled |

| 4 |

Invert alarm_lo output (active low) |

| 5 |

Invert alarm_hi output (active low) |

| 6 |

Invert preset output (active low) |

| 7 |

Invert capture output (active low) |

| 8-9 |

Counter function (functions are described

later) |

| 10-11 |

Reserved, must be 0 |

| 12 |

Invert input A (only for functions 01 and

10) |

| 13 |

Invert input B (only for functions 01 and

10) |

| 14-31 |

Reserved, must be 0 |

Bits meaning in incremental counter

configuration The counter is capable to handle three input signal

types, depending on its function. Counter function is

defined by configuration bits 8 and 9 as follows:

00 - quadrature counter: A and

B inputs are used as inputs from positional or

angle sensors using quadrature encoding (every edge causes

counting, phase shift of A and B

inputs determines up or down direction). It is not possible

to invert A and B input signals in

this case. 01 - up/down counter: The

A input causes counter increment, input

B causes counter decrement. Input logic (if the

rising or falling edge is active) is defined by bits 12 and

13 of configuration register. 10 - step/direction counter: The counter is

incremented or decremented by the logical input A.

The direction (whether counter is incremented or

decremented) is defined by the logical input B.

Input logic (if the rising or falling edge is active) is

defined by bits 12 and 13 of configuration

register. 11 - invalid value, reserved for future

use.

Alternative way to define mode is using a list of

keywords:

Counter function is defined by one of the following

three identifiers: quadrature, up_down,

step_direction enable_alarm_lo—alarm_lo output enabled (when counter

underflows CompareLo value) enable_alarm_hi—alarm_hi output enabled (when counter

overflows CompareHi value) enable_preset—preset input enabled enable_capture—capture input enabled invert_alarm_lo—Invert alarm_lo output (active

low) invert_alarm_hi—Invert alarm_hi output (active

low) invert_preset—Invert preset output (active

low) invert_capture—Invert capture output (active

low) invert_a—Invert

input A (only for up_down and step_direction) invert_b—Invert

input B (only for up_down and step_direction)

Mode from the previous example can be defined as

follows:

mode = step_direction, enable_preset, enable_capture, invert_a, invert_b

Digital output modules DO1, DO2 and DO3

Module type designation in parameter file: DO1,

DO2, DO3. Data channels: 8 output channels of boolean

type. Control channel: output channel of shortcard

type sets values of all 8 outputs as one number when

written—every bit is set to

appropriate output. Mode: N/A.

Analog input module AI1

Module type designation in parameter file: AI1. Data channels: 8 input channels of real

type. Control channel: output channel of shortcard

type sets input range—the range

number corresponds to value defined in the mode

parameter. Mode: number 0 to 3 defines input voltage range,

actual range depends also on module hardware settings and

available ranges are described later.

There are a small array of jumpers on the module

printed circuit board (PCB), associated with every input

channel. Jumper configurations are described in the module

technical documentation. Basically, jumpers define two

settings:

So the actual input range depends on the mode of analog

inputs (defined by the parameter mode in

parameter file and/or by control channel write) and also on

the BIAS jumpers position.

Hint: While the mode can be set for the whole module only

(for all 8 channels), jumpers can be set independently for

each channel. Every channel can be configured to measure

voltage or current and every channel can have input range

multiplied 4 times by BIAS jumpers. It is also clear

that while the jumpers can be set only while the unit is

unplugged fro USB and not powered, the mode can be changed

programmatically. But thanks to Plug and Play features of

DataLab IO it is not necessary to

stop the application—the device can be

unplugged, jumpers can be altered and the plugged

again. Input voltage ranges of individual modes for both BIAS

jumper positions are:

| BIAS |

mode |

Max. voltage between inputs |

Full range |

| on |

0 |

+/-20 V |

40 V |

| on |

1 |

+/-10 V |

20 V |

| on |

2 |

+/-5 V |

10 V |

| on |

3 |

+/-2,5 V |

5 V |

| off |

0 |

+/-5 V |

10 V |

| off |

1 |

+/-2,5 V |

5 V |

| off |

2 |

+/-1,25 V |

2,5 V |

| off |

3 |

+/-0,625 V |

1,25 V |

Input ranges of analog inputs The BIAS column represents BIAS jumper positions on the

module PCB.

Values “Max. voltage between inputs” a

“Full range” needs a brief explanation:

No one terminal connector pin is grounded so it does

not matter if the input voltage is -20 V and 0V,

-10 V and +10 V or 0 V and

+20 V. This is why the maximal voltage between inputs

is defined instead simply symmetrical difference. The

maximum difference causes reading of the maximum number from

the ADC 32767 (215 - 1). Inputs are fully bipolar so when we switch the input

polarity, negative numbers will be read. After connecting

0 V and -20 V number -32768 (-215) will be read. Although the maximal voltage between

pins is 20 V, both polarities creates full input range

40 V.

Hint: Ranges 10 V and 5 V can be

measured when BIAS is on (modes 2 and 3) or off (modes 0 and

1). Due to ADC internal workings and signal filtration it is

always better to use highest input ranges. It is recommended

to configure BIAS off and use modes 0 and 1 for these

ranges. Analog input module AI2

Module type designation in parameter file: AI2. Input channels: 8 channels of real type

for analog inputs. Output channels: 8 channels of shortcard

type for setting of input range of related channel. Value 0

turns off measuring of the particular input.

| Range |

Voltage input |

Current input |

| 0 |

input inactive |

input inactive |

| 1 |

+/-10 V |

N/A |

| 2 |

+/-5 V |

N/A |

| 3 |

+/-2.5 V |

+/-20.8 mA |

| 4 |

+/-1.25 V |

+/-10.4 mA |

Input ranges of AI2 analog input

module The default input range is +/-10 V. Control channel: output channel of longcard

type sets input range for all 8 inputs. Every input is

represented by 4 bits, so 8 channels occupy 32 bits. Writing

to control channel the replaces eight writes to all output

channels. Mode: number representing input range for all 8

inputs, every 4 bits define range for one input channel (the

value has the same meaning as value written to control

channel). Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 2;

mode2 = 4; Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Unit: module supports values in three units—native A/D converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU. If the ADU unit is

chosen, minimal value (e.g. -10 V) is represented by the number -32768

and maximal value (e.g. 10V) by number 32767. If physical

units are chosen, numbers -10 a nd 10 are directly

read.

There is a jumper on the module PCB associated with every

input channel. Closing the jumper causes a precision

120 Ω resistor is inserted into the input, which

changes voltage input into the current one.

Hint: Input ranges can be defined for every input channel

independently by the application program. But the voltage or

current mode is selected by jumper on the PCB and this cannot

be performed on application runtime. The AI2 module allows not only input range setting for

individual inputs, but also allows switching each input off.

Skipping of particular input speeds up the sampling frequency

of remaining inputs.

The module is able to sample data at frequency 50 Hz (50 samples per second) on one channel.

If all 8 channels are measured, the sampling speed is

6.25 Hz. If it

is for instance necessary to sample data 10× per second, only 5 channels can be turned

on, remaining 3 channels must be turned off.

It is not necessary to wait for the digital filter to

settle down when only one channel is measured and the input

multiplexer is not switched. The data sampling frequency is

then 200 Hz. But keep on mind

that the A/D converter is not able to pass the step over the

full input range to its output at this speed. If the input

voltage changes e.g. from -10 V to +10 V, the converter needs 4 cycles to

propagate the step to the output. So the sampling frequency is

again 50 Hz.

Analog input module AI3

Module type designation in parameter file: AI3. Input channels: 8 channels of real type

for analog inputs. Output channels: 8 channels of cardinal

type for setting of input range of related channel. Values 0

and 8 turns off measuring of the particular

input.

| Range |

Voltage input |

Current input |

| 0 |

input inactive |

input inactive |

| 1 |

+/-10 V |

N/A |

| 2 |

+/-5 V |

N/A |

| 3 |

+/-2 V |

+/-20 mA |

| 4 |

+/-1 V |

+/-10 mA |

| 5 |

+/-0.5 V |

+/-5 mA |

| 6 |

+/-0.2 V |

+/-2 mA |

| 7 |

+/-0.1 V |

+/-1 mA |

| 8 |

input inactive |

input inactive |

| 9 |

0..10 V |

N/A |

| 10 |

0..5 V |

N/A |

| 11 |

0..2 V |

0..20 mA |

| 12 |

0..1 V |

0..10 mA |

| 13 |

0..0.5 V |

0..5 mA |

| 14 |

0..0.2 V |

0..2 mA |

| 15 |

0..0.1 V |

0..1 mA |

Input ranges of AI3 analog input

module The default input range is +/-10 V. Control channel: output channel of longcard

type sets input range for all 8 inputs. Every input is

represented by 4 bits, so 8 channels occupy 32 bits. Writing

to control channel the replaces eight writes to all output

channels. Mode: number representing input range for all 8

inputs, every 4 bits define range for one input channel (the

value has the same meaning as value written to control

channel). Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 2;

mode2 = 4; Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Unit: module supports values in three units—native A/D converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU. If the ADU unit is

chosen, minimal value (e.g. -10 V) is represented by the number -32768

and maximal value (e.g. 10V) by number 32767. If physical

units are chosen, numbers -10 a nd 10 are directly

read.

There is a jumper on the module PCB associated with every

input channel. Closing the jumper causes a precision

100 Ω resistor is inserted into the input, which

changes voltage input into the current one.

Hint: Input ranges can be defined for every input channel

independently by the application program. But the voltage or

current mode is selected by jumper on the PCB and this cannot

be performed on application runtime. The AI3 module allows not only input range setting for

individual inputs, but also allows switching each input off.

Skipping of particular input speeds up the sampling frequency

of remaining inputs.

The module is able to sample data at frequency 50 Hz (50 samples per second) on one channel.

If all 8 channels are measured, the sampling speed is

6.25 Hz. If it

is for instance necessary to sample data 10× per second, only 5 channels can be turned

on, remaining 3 channels must be turned off.

It is not necessary to wait for the digital filter to

settle down when only one channel is measured and the input

multiplexer is not switched. The data sampling frequency is

then 200 Hz. But keep on mind

that the A/D converter is not able to pass the step over the

full input range to its output at this speed. If the input

voltage changes e.g. from -10 V to +10 V, the converter needs 4 cycles to

propagate the step to the output. So the sampling frequency is

again 50 Hz.

Analog output module AO1

Module type designation in parameter file: AO1. Data channels: 8 output channels of real

type. Control channel: N/A. Mode: N/A. Unit: module supports values in three units—native D/A converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU.

Analog output module provides 8 voltage analog outputs with

the range 0 to +10 V. D/A

converter has 12 bit resolution.

Each D/A converter count equals to

2.5 mV output voltage change.

First four of eight outputs can be configured as current

outputs with range from 0 to 20 mA using jumpers on the

module PCB. Due to the high resolution of the DAC the 4 to

20 mA range is implemented by software limitation of 0 to

20 mA range.

Combined analog input and digital input/output module

AD1

Module type designation in parameter file: AD1. Input channels:

4 channels of real type for every

analog input. The following 4 channels of boolean

type for every digital output. These channels return

current logical value of digital inputs. The are

intended for reading of DC signals. Next 4 channels of boolean type

return logical value of digital input evaluated as AC

input. The rules to evaluate true and false of AC signal

are described in the description of digital input modules. Output channels:

4 channels of cardinal type for

setting of input range of related channel. Values 0 and

8 turns off measuring of the particular

input. Input ranges of analog input channels equal

to the input ranges of the AI3 module. They are

described in detail in the AI3 module

description. The following 4 channels of boolean

type for every digital output. Control channel: output channel of longcard

type sets input range for all 4 inputs. Every input is

represented by 4 bits, so 4 channels occupy 16 bits. Writing

to control channel the replaces writes to first four output

channels. Mode: number representing input range for all 4

inputs, every 4 bits define range for one input channel (the

value has the same meaning as value written to control

channel). Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 2;

mode2 = 4; Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Unit: module supports values in three units—native A/D converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU. If the ADU unit is

chosen, minimal value (e.g. -10 V) is represented by the number -32768

and maximal value (e.g. 10V) by number 32767. If physical

units are chosen, numbers -10 a nd 10 are directly

read.

AD1 module analog inputs equal to the AI3 module inputs.

Choosing voltage or current inputs, switching input ranges,

sampling rate and other characteristics are described in the

AI3 module description. But

because the AD1 module has only 4 analog input channels, the

input sampling rate is 12.5 Hz, not 6.25 Hz as in the case of AI3 module.

Combined analog input/output and digital input/output

module AD2

Module type designation in parameter file: AD2. Input channels:

4 channels of real type for every

analog input. The following 2 channels of boolean

type for every digital output. These channels return

current logical value of digital inputs. The are

intended for reading of DC signals. Next 2 channels of boolean type

return logical value of digital input evaluated as AC

input. The rules to evaluate true and false of AC signal

are described in the description of digital input modules. Output channels:

4 channels of cardinal type for

setting of input range of related channel. Values 0 and

8 turns off measuring of the particular

input. Input ranges of analog input channels equal

to the input ranges of the AI3 module. They are

described in detail in the AI3 module

description. The following 2 channels of real

type for analog outputs. Next 2 channels of boolean type for

every digital output. Control channel: output channel of longcard

type sets input range for all 4 inputs. Every input is

represented by 4 bits, so 4 channels occupy 16 bits. Writing

to control channel the replaces writes to first four output

channels. Mode: number representing input range for all 4

inputs, every 4 bits define range for one input channel (the

value has the same meaning as value written to control

channel). Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 2;

mode2 = 4; Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Unit: module supports values in three units—native A/D converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU. If the ADU unit is

chosen, minimal value (e.g. -10 V) is represented by the number -32768

and maximal value (e.g. 10V) by number 32767. If physical

units are chosen, numbers -10 a nd 10 are directly

read.

AD2 module analog inputs equal to the AI3 module inputs.

Choosing voltage or current inputs, switching input ranges,

sampling rate and other characteristics are described in the

AI3 module description. But

because the AD2 module has only 4 analog input channels, the

input sampling rate is 12.5 Hz, not 6.25 Hz as in the case of AI3 module.

Analog outputs can be configured as voltage or current

outputs using jumpers on the module PCB. Voltage output range

is 0 to 10 V, current output

range is 0 to 20 mA. The used D/A converter has

8-bit resolution and one count corresponds to

41.5 mV or

0.083 mA.

Combined analog input/output module AIO1

Module type designation in parameter file: AIO1. Input channels: Output channels:

4 channels of cardinal type for

setting of input range of related channel. Values 0 and

8 turns off measuring of the particular

input. Input ranges of analog input channels equal

to the input ranges of the AI3 module. They are

described in detail in the AI3 module

description. The following 4 channels of real

type for analog outputs. Control channel: output channel of longcard

type sets input range for all 4 inputs. Every input is

represented by 4 bits, so 4 channels occupy 16 bits. Writing

to control channel the replaces writes to first four output

channels. Mode: number representing input range for all 4

inputs, every 4 bits define range for one input channel (the

value has the same meaning as value written to control

channel). Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 2;

mode2 = 4; Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Unit: module supports values in three units—native A/D converter counts (ADUs), volts or

millivolts and amperes or milliamperes. Preferred units are

defined using one of the predefined keywords: ADU,

V, mV, A or

mA. Units can be defined for all output

channels (using key unit) or independently for

each channel (using keys unit1, unit2,

etc.). The default unit is ADU. If the ADU unit is

chosen, minimal value (e.g. -10 V) is represented by the number -32768

and maximal value (e.g. 10V) by number 32767. If physical

units are chosen, numbers -10 a nd 10 are directly

read.

AIO1 module analog inputs equal to the AI3 module inputs.

Choosing voltage or current inputs, switching input ranges,

sampling rate and other characteristics are described in the

AI3 module description. But

because the AIO1 module has only 4 analog input channels, the

input sampling rate is 12.5 Hz, not 6.25 Hz as in the case of AI3 module.

Analog outputs can be configured as voltage or current

outputs using jumpers on the module PCB. Voltage output range

is 0 to 10 V, current output

range is 0 to 20 mA. The used D/A converter has

12-bit resolution and one count corresponds to

2.5 mV or

0.005 mA.

Module for Resistive Temperature Detectors RTD1

Module type designation in parameter file: RTD1. Input channels: 4 channels of real type

for every input. Output channels: 4 channels of cardinal

type for setting of input range of related channel. Range

values are bit-oriented and they are constructed according

to the same rules valid for mode parameter described below.

Value 0 switches off particular input. Allowed range values

are stated in the following table.

| Detector |

Pt100 |

| Temperature range |

Temperature Coefficient of Resistance

(TCR) |

| 3850 |

3750 |

3911 |

3926 |

| –50..+150°C |

1 |

17 (11H) |

33 (21H) |

48 (31H) |

| 0..+100°C |

2 |

18 (12H) |

34 (22H) |

49 (32H) |

| 0..+200°C |

3 |

19 (13H) |

35 (23H) |

50 (33H) |

| 0..+400°C |

4 |

20 (14H) |

36 (24H) |

51 (34H) |

| –50..+50°C |

5 |

21 (15H) |

37 (25H) |

52 (35H) |

| Detector |

Pt1000 |

| Temperature range |

Temperature Coefficient of Resistance

(TCR) |

| 3850 |

3750 |

3911 |

3926 |

| –50..+150°C |

6 |

22 (16H) |

38 (26H) |

53 (36H) |

| 0..+100°C |

7 |

23 (17H) |

39 (27H) |

54 (37H) |

| 0..+200°C |

8 |

24 (18H) |

40 (28H) |

55 (38H) |

| –50..+50°C |

9 |

25 (19H) |

41 (29H) |

56 (39H) |

| Detector |

Ni1000 |

| Temperature range |

Temperature Coefficient of Resistance

(TCR) |

| 5000 |

6180 |

6370 |

6720 |

| –50..+150°C |

70 (46H) |

86 (56H) |

102 (66H) |

118 (76H) |

| 0..+100°C |

71 (47H) |

87 (57H) |

103 (67H) |

119 (77H) |

| 0..+200°C |

72 (48H) |

88 (58H) |

104 (68H) |

120 (78H) |

| –50..+50°C |

73 (49H) |

89 (59H) |

105 (69H) |

121 (79H) |

| Input off |

0 |

Ranges for RTD1 module Default value is 1 (Pt100/3850, -50 až

+150°C). Control channel: output channel of longcard

type sets input range for all 4 inputs. Every input is

represented by 1 byte, so 4 channels occupy 32 bits.

Writing to control channel the replaces writes to all four

output channels. Mode: number representing input range for all 4

inputs, every byte defines range for one input channel (the

value has the same meaning as value written to control

channel). Particular byte value is bit-oriented and consists

of two groups. Bits 0 to 3 determines one of nine available

resistance ranges. Bits 4 to 6 determines Temperature

Coefficient of Resistance (TCR), which depends on the RTD

type. Bit 7 is not used and must be 0. Bits 0 to 3

meaning:

| Bit 0 to 3 |

Resistance range [Ω] |

Temperature range [°C] |

| 0000 |

input off |

input off |

| 0001 |

75..160 |

–50..+150°C |

| 0010 |

91..150 |

0..+100°C |

| 0011 |

91..180 |

0..+200°C |

| 0100 |

91..240 |

0..+400°C |

| 0101 |

75..130 |

–50..+50°C |

| 0110 |

680..2000 |

–50..+150°C |

| 0111 |

910..1800 |

0..+100°C |

| 1000 |

910..2500 |

0..+200°C |

| 1001 |

680..1300 |

–50..+50°C |

Temperature and resistance ranges Bits 4 to 6 meaning:

| Bit 4 to 6 |

TCR [PPM/°C] |

RTD Type |

| 000 |

3850 |

Pt100/Pt1000 |

| 001 |

3750 |

Pt100/Pt1000 |

| 010 |

3911 |

Pt100/Pt1000 |

| 011 |

3926 |

Pt100/Pt1000 |

| 100 |

5000 |

Ni1000 |

| 101 |

6180 |

Ni1000 |

| 110 |

6370 |

Ni1000 |

| 111 |

6720 |

Ni1000 |

Temperature Coefficient of Resistance

(TCR) Mode can be also

defined individually for every channel using keywords mode1,

mode2, etc. mode1 = 5

mode2 = 5

mode3 = 56H

mode4 = 56H Mode definition and writing to control channel upon

application startup are equivalent. If the input ranges are

not changed during application runtime mode definition is a

better way. If the ranges are defined in the program, mode

definition is superfluous. Another (and more clear)

method of mode definition is using of predefined keywords.

Mode parameter is the written as follows: mode = <sensor>, <coefficient>, <range> where individual items are:

<sensor>—RTD type. Available values are: Pt100,

Pt1000, Ni1000. The default

value is Pt100. <coefficient>—Temperature Coefficient of Resistance

(TCR). This coefficient is sometimes marked as α (

α = TCR / 106). Available values: 3850, 3750,

3911, 3926, 5000,

6180, 6370, 6720.

Default value TCR is 3850 PPM/°C. <range>—temperature range. Allowed ranges are 1 to

5 according to the following table:

| Range number |

Temperature range [°C] |

| 1 |

–50..+150°C |

| 2 |

0..+100°C |

| 3 |

0..+200°C |

| 4 |

0..+400°C |

| 5 |

–50..+50°C |

Temperature ranges Unit: module supports values in different

units—native A/D converter counts

(ADUs), Ohms, degrees Celsius, Fahrenheit of Kelvins.

Preferred units are defined using one of the predefined

keywords: ADU, Ohm, C,

F or K. Units can be defined

for all output channels (using key unit) or

independently for each channel (using keys unit1,

unit2, etc.). The default unit is ADU. If

the ADU unit is chosen, minimal value is represented by the

number 0 and maximal value by number 65,535.

The value 0 can also mean short circuit on input or

disconnected detector. Value 65,535 can mean

overflow of the selected temperature range. If physical

units are chosen, numbers in particular units are directly

read.

Hint: Input ranges can be defined for every input channel

independently by the application program. Inputs are sampled at the same speed as in the case of the

AI3 module. However, sampling speed is not critical in the

case of temperature measurement using RTD.

Mode and control channel usage

The same module configuration can be often defined in two

ways—by writing to control channel or

by setting the mode parameter in the parameter file. The

numerical value is the same in both cases. Writing the control

channel on application startup (e.g. in OnStartup() procedure

of some instrument) has the same effect as defining the mode

parameter in the parameter file.

The driver stores value written to control channel and uses

it as module mode. If the module is disconnected and then

connected again, the module is initialized with the last value

written to the control channel and not with mode value defined

in the parameter file.

Driver-specific error codes

The driver generates the following error

codes:

device unplugged: DataLab IO unit is without power (applicable to

self-powered units only) or the USB cable is unplugged. This

error should not occur if the DataLab IO unit is embedded to DataLab PC computer, because the power and USB cabling

is internal in this case. wrong module: The module, plugged into the

particular DataLab IO slot, is of

different type that stated in the parameter file. It is usually

easier to update the parameter file than to swap modules in the

device. If the parameter file was created automatically by the

driver configuration tool, this error should not occur. module does not support control channel read:

Application attempted to read control channel of module, which

does not support it (see chapterChannels and

modes of individual module types). module does not support control channel write:

Application attempted to write control channel of module, which

does not support it (see chapterChannels and

modes of individual module types).

Module positions and device slots

DataLab IO4 has four slots marked by

letters A, B, C and D. These slots are placed in the device as

displayed on the picture:

Module positions on the DataLab IO unit Take care to orient the unit properly—slots A and B are on top when the device blue LED

and also the USB and power connectors are on the right side.

The slot letters are necessary only for users—they do not affect the device functionality. Any

module can be placed to any slot. The device automatically detects

plugged module types and adopts to the current configuration. But

if the device is used with the Control Web

application, the parameter file contains parameters for concrete

modules and it is necessary to uniquely identify these

modules.

DataLab IO1 has only one module slot

marked A. This is why the parameter file for DataLab IO1 unit should have only the [module_a]

section.

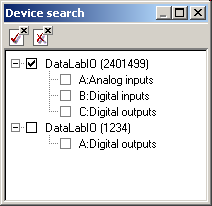

Driver configuration in the Control Web

development environment

The Control Web development environment offers

tools for comfortable driver configuration. This tool

automatically creates driver parameter file (.par) and driver map

file (.dmf) according to the application author's needs.

The driver configuration tool scans the USB bus to search all

DataLab IO units plugged to the computer.

All units including their identifiers and plugged modules are

displayed in a tree.

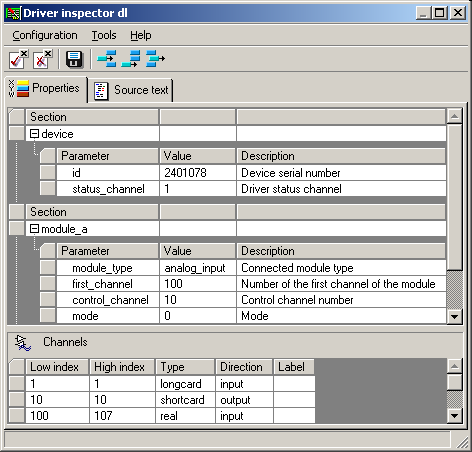

Scanning of all connected DataLab IO devices It is possible to choose the device with which the particular

driver will communicate. Device parameters can be edited using the

structured sheet editor, showing parameters of individual

sections.

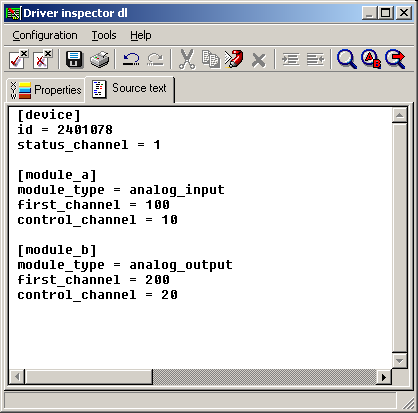

Driver parameter editing The driver configuration tool can create both parameter and

mapping files from defined parameters. It is of course possible to

edit these files using arbitrary text editor.

The parameter file in the text form DataLab IO system driver

The operating system needs proper drivers to correctly detect

and handle all USB devices. There is a system driver on the CD-ROM

supplied with every DataLab IO device.

Driver files are placed in '\English\DataLab

IO_USB\Drivers\Windows' directory. This directory contains

only two files: 'dlusb.sys' (the driver itself) and

'dlusb.inf' (installation information). The driver can

be installed explicitly by clicking the 'dlusb.inf'

file by right mouse button and choosing the Install

menu item. But this way is not usual. The best way to install the

system driver is just plug the DataLab IO

device to USB port. The operating system will detect new USB

device and prompts the user to enter path to driver files. It is

possible to enter the path to '\dlusb' on CD-ROM or

just to let the system to search the CD-ROM for drivers.

Hint: It is not necessary to install the driver from the

CD-ROM. Driver files can be copied to any disk storage. If for

instance the target machine is not equipped with the CD-ROM drive,

it is possible to copy driver files to USB Flash Disk and to

install them from that copy. Warning: The 'dlusb.sys' driver is not signed by

digital signature. Windows notifies the user about that and asks

if the installation should continue. If you want to install the

driver, just continue with installation. Digital signature is only

a formal and should ensure using only drivers signed by Microsoft.

It does not affect driver functionality. Operating system support

The DataLab IO devices can

theoretically work with any operating system supporting USB

interface. However, as stated earlier, every operating system

requires proper driver to work with USB device. Currently only

Windows driver is supplied with DataLab IO devices.

But there are also differences among various Windows

versions. The 'dlusb.sys' corresponds to WDM

(Windows Driver Model) specification. WDM drivers should work

in Windows 98SE, Windows Me and also in Windows 2000 and

Windows XP. But there are APIs missing in Windows 9x (Windows

98 and Windows Me), necessary to correctly detect device

arrival/removal from user mode. This is why the driver

requires Windows 2000 and better versions of Windows (e.g.

Windows XP).

History of function enhancements

Whenever the functionality of DataLab IO is enhanced, the new version of software

support must be released. Both DataLab IO system driver (the 'dlusb.sys'

file) and Control Web and Active X driver (the 'dldrv.dll' file)

must be upgraded together. This is why the major and minor

version numbers of both files are the same. | Version 1.0 | The first released version. | | Version 1.1 | Analog output modules (AO1) are supported by

the drivers. | | Version 1.5 | System driver version number is synchronized with

Control Web and Active X driver (the 'dldrv.dll'

file). | | | The USB communication is monitored by watchdog timer in

the DataLab IO device. If the

communication fails (e.g. due to EMI if the USB cable with

broken shielding is used), the device electrically disconnects

itself and reconnects again to restore connection to PC.

Communication is restored approximately after 2 s. | | Version 1.6 | The drivers newly support digital counter input and

incremental counter modules (CNT1, CNT2). | | | It is possible to explicitly declare channel directions

in the parameter file using new keywords (first_input_channel

and first_output_channel). | | | The device can return its identification number through

id_channel. | | | Numbers in parameter file can be written not only in

decimal format, but also in binary and hexadecimal notation.

Numbers in binary notation should be followed by letter

“B”, numbers in hexadecimal notation should be followed

by letter “H”. | | Version 1.7 | It is possible to define logical parameter reset_outputs

in the [device] section. If the parameter is true

(reset_outputs = true), all output

channels are reset to their initial state (the sate in which

channels are when the device is powered on) when the application

is terminated or when the host PC (or connection to host PC)

fails. | | Version 1.8 | Module types in the parameter file are identified

directly by the module name, not by symbolic name. For instance

the DI1 is used instead of digital_input,

CNT1 instead of counter etc. Older

denotations (digital_input, analog_output,

etc.) are accepted to maintain backward compatibility, but newly

added modules must be identified by module name, no new symbolic

name is introduced. | | | Support for physical units was added to the driver (new

parameter file keyword unit was introduced). Analog

modules can define if the read/written values are expressed in

native A/D or D/A converter steps (ADU), in volts (V) or

amperes (A). Units can be also defined for individual channels

using keywords unit1, unit2,

etc. | | | If the module allows mode definition, it can be defined

for individual channels using new keywords mode1,

mode2, etc. | | | Mode can be defined also as list of symbolic keywords in

addition to numbers (e.g. mode = step_direction, enable_preset). | | | The driver stores configuration values (values written to

module control channel) and uses them as mode when the device is

unplugged and plugged again. If the configuration is changed by

the program, it is no longer necessary to capture the driver

exception notifying about module plug in and write the control

channel—driver does it internally for

all modules with the exception of already discontinued AI1

module. | | | Added support for AI2 analog input

module. | | Version 1.9 | Added support for AI3 analog input

module. | | | Added support for AD1 analog input module

with digital I/O. | | Version 1.10 | Added support for AD2 analog I/O and digital

I/O module. | | | Added support for RTD1 module. | | | Parameter id accepts number or number

list. |

|