|

This interconnection within one program environment significantly

simplifies not only the development of new applications, but also the

resulting solution is cheaper than other concepts. In most cases, we

can use a single computer to which both cameras and industrial input /

output units are connected and which is also connected to a computer

network and company information system. This computer usually runs the

graphical user interface of the application, the database SQL server,

the web server, visual inspection and machine vision tasks, as well as

the entire logic of the automation application.

Fig. 1: Machine vision as part of the control system. The

range of functionality makes Control Web an effective industry

digitization tool for virtually any customized solution. If additional remote automation racks are needed, each can be

connected via Ethernet and TCP/IP networks. An example of such a

remote switchboard is shown in Fig. 2. The efficiency of the solution

and the advantageous price of all hardware and software is obvious in

such conceived systems.

Fig. 2: The automation switchboard is connected with a

single Ethernet cable thanks to DataLab units with TCP/IP

protocol. With the advent of the new generation of Control Web 8, several

features have been added to further enhance machine vision integration

capabilities.

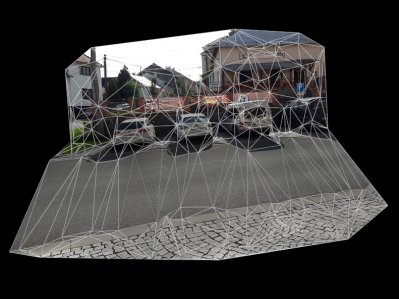

Fig. 3: Demonstration of stereoscopic capturing of outdoor

scene space. The virtual instrument builds a 3D model of the sensed

space and it can determine eg. the position of cars and their

distance from the camera. A new type of data data objects for transferring general binary

data has been added to machine vision. This type corresponds to data

elements of the data type in the Control Web environment. Virtual

instruments in the application program and steps in the machine vision

chain can now efficiently exchange blocks of arbitrary data. The type

of data and the format of its storage is not prescribed in any way. In

some tasks, such as further work with detected significant image

points in an application program, this technique of transferring

binary data blocks brings significant acceleration. New possibilities

of cooperation of automation application with a chain of machine

vision steps can be well demonstrated eg by virtual instruments for

displaying spatial scene in the form of 3D object. The image data is

captured by a stereoscopic pair of cameras. This virtual instrument

has several peculiarities. It depicts a scene captured by cameras, but

does not communicate directly with the cameras itself. It needs not

only two images from cameras, but also information about feature

points and their descriptors found in these two images. It must

therefore cooperate with machine vision, which, by means of the point

detection step, fills data elements of the data type with found

descriptors of these points. Similar to the point descriptors, the

actual image from each camera is transmitted to the virtual instrument

via data elements of the data type. A virtual instrument can be very

useful in applications where we need information about the distances

of objects in an image, when we have to find objects at different

distances or avoid collisions with objects in space while moving. By

means of data elements of the data type, any image can also be

transmitted, for example, to display devices located anywhere in the

3D space of the scene.

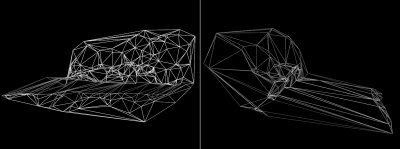

Fig. 4: 3D model of the captured scene, created from two

camera images We can also use VisionLab's ability to locate feature image points

and calculate descriptors describing their surroundings efficiently

and with maximum use of massively parallel GPU performance, to detect

general objects in images. Feature points are searched on a scale of

several scales, then objects can be detected independently of their

rotation and brightness, but also independently of their size. A set

of descriptors that characterize objects that we want to identify

further in the image data can provide detection steps in both files

and data elements of the data type.

Fig. 5: In 3D space model it is possible to measure

distances of individual surfaces from cameras

Fig. 6: Via the detected feature points, eg. traffic signs

can be identified in the camera image Now that the new eighth generation of Control Web is available, it

is also worth noting that the development version of Control Web can

be downloaded free of charge from www.controlweb.eu and used on an

unlimited number of free installations. The license is only required

if the application is required to run continuously. All VisionLab

drivers and vision systems can be used as well.

Roman Cagaš

|