|

Unlike other areas of industrial automation, the particularity of

machine vision applications is high number of unsuccessful solutions.

Despite all the profession advances, the design of machine vision is

relatively very difficult to understand and respect the basic

principles of imaging and work with image data. The most important is

the first phase of the proposal, that means determination the

geometric arrangement of the inspection system, camera choice, lens,

illumination and selection of appropriate hardware and software for

image processing. If you make a major mistake here, the probability of

failure is very high.

We must make the most important decisions first. The issue is quite

extensive and this article may include only a tiny fraction.

General task configuration

Choice of spatial configuration relatively determines the type and

number of cameras and illuminating units and the requirements on the

lens focal length. We must be sure, from what direction and distance

will the camera capture the scene, we must also set sufficient cameras

resolution, possibly need to use multiple cameras. It is needed to

decide about the way of illuminating and its color at the same time –

this is connected with the elimination of distractive light and

therefore the shading proposal and the possible need to use color or

polarizing filters in the camera.

Hardware and software image processing

Here we have a choice between two concepts:

Use of so-called smart cameras and image processing within

the capabilities of these cameras Connecting the cameras to the computer and image processing

by standard computer

An essential factor here is surprisingly not the cost of final

solution – both concepts are about equally expensive. Especially

important is the requirement on computing performance, flexibility and

variability of software. Smart cameras do image processing themselves

and are externally equipped with binary outputs, enabling to signalize

the result of the process. Usually do not allow free programming, it

is only possible to configure them through serial line or Ethernet

connection. They are usually equipped with specialized signal

processors or low consumption RISC processors with tact in hundreds of

MHz and simple real-time operating systems. These facts already

point to their limitations. Smart cameras are equipped with only a few

basic tools for image processing and are suitable only for simple

tasks. On the other hand, many tasks are usually dealt with

surprisingly simple means, and here the integrated cameras suit.

Estimate the situation in advance requires a lot of knowledge, sense

and experience. Where it is necessary to cope with such variable

scene, responding to changes in positions and shapes of objects,

lighting changes or to solve complex and performance-intensive

algorithms, we quickly run into limits that are firm and

insurmountable. Effort to solve by smart cameras tasks beyond their

means, is the reason for many failed projects.

Connecting the camera to a standard PC is a necessary choice for

complex applications, but also for simpler applications leaves us more

room to correct any inaccuracies in the initial estimate of

requirements. Performance of modern processors dramatically exceed

even the best smart cameras and embedded computer does not have to

take the form of a large box with several fans. In addition, many

typical operations with the image data can be accelerated by parallel

processing on multiple cores simultaneously. Some software systems,

and the spearhead of these technologies is e.g. VisionLab machine

vision system, can exploit the massive parallel performance of current

graphics processors. While today's CPUs have up to four cores, GPUs

divide the calculation e.g. to 240 cores. Such a system is capable

with image in real-time to perform until recently unthinkable

operations.

Even with more than adequate programming environment we sometimes

encounter the absence of the required functions or its poor

performance. The possibility of adding custom code can give us peace.

And even if it did not help to meet our requirements, at worst, we can

change the entire software system for machine vision and avoid failure

in dealing with contract. More room for operating is always handy.

In many cases it is sufficient when the only output in visual

inspection system is a binary output, signalizing a faulty product,

more often machine vision systems do not operate separately from the

rest of the world, but is required their integration into enterprise

information systems.The programming environment should allow the

inclusion of a visual inspection into wider context of operating and

visualization system, should transfer all data network, including

image data, communicate with the PLC, cooperate with SQL servers, HTTP

servers etc.

Further, suppose we propose a system where the cameras are

connected to a standard PC. It remains to choose the right camera,

lens and illumination.

Camera

There are so many criteria for selecting the camera, we can

consider the CCD or CMOS detector, chip size and resolution,

monochrome or color sensor. In the case of the color sensor may be a

single-chip implementation, three-chip color design or sequential

shooting with black and white sensor and color filters. Camera

connection may be analog or digital. In the case of a digital

interface we have a choice of Ethernet / IP, USB or Firewire. Digital

cameras can be run either with a fixed frame rate, can be externally

triggered, can run free with the accumulation of light, may provide

variously compressed data stream or can provide unbiased raw data,

etc. – when selecting the camera, really confusing number of criteria

plays the role.

Let's simplify the selection for the purposes of machine

vision. Above all, we must choose the appropriate point resolution –

for the purposes of measurements in image the resolution determines

the size of the measured object and demand for its measurement

accuracy. One pixel must theoretically correspond to the measurement

accuracy. This theoretical accuracy and reproducibility of measurement

is reduced by the effect of noise and unwanted image artifacts,

necessarily occurring in the lossy compression of image data.

Sometimes we can use statistical methods to reach the Sub-pixel

measurement accuracy, and generally without the knowledge of things

but it is not possible to design a system like this. In the case of

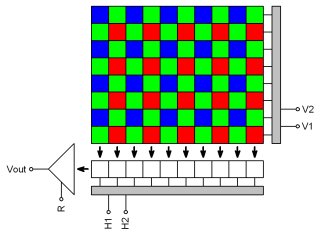

single-chip color cameras has to be taken into account approximately

half the linear resolution ability. In color mosaic, usually from four

pixels, two pixels are green, one red and one blue. This brings not

only the lower resolution ability, but also as e.g. image cross-shift

in different color channels.

Arrangement of color mosaic on CCD chip In addition to resolution, we must choose connection and type of

camera. We probably reject an analog camera for machine vision needs.

Digital cameras are usually connected at a bigger distance via

Ethernet and at a short distance through the USB. The principle of

cameras digital connection itself is not the guarantee of image

quality. The cameras are generally designed very similarly - the vast

majority of digital CCD camera includes similar integrated camera

controller, that digitizes data from the CCD, balances color,

interpolates colors from the Bayer mosaic and lossy

compresses data to MJPEG or MPEG4 stream. Considering the

compromisingly reduced characteristics of integrated image processor,

the quality of these operations is always visibly limited and the

resulting image is so burdened with significant undesirable artifacts.

Therefore, already at the stage of conceptual design of machine vision

we must have a very precise idea of what image quality we need.

Purity, stability and accuracy of image certainly is not essential for

all types of applications, sometimes it is surprising that visual

inspection works based on the presence or absence of a few blurry

spots in the pre-defined positions. But for more complex applications

it is the image quality what makes stable and therefore successful

operation of inspection system decisive. Best image quality achievable

bring cameras, which provide RAW image data. The image is not

transformed by these cameras, color balanced, interpolated nor

compressed. It delivers unmatched image precision, which is available

in the connected computer, and there can be processed without any

compromises limiting its quality. High bitrate can be sometimes an

obstacle between the camera and computer. In short-distance

connections these requirements are perfectly solved by the USB 2.0

interface with bitrate up to 480 Mb/s (one cable at 5 meters and

up to 30 meters when using active extension and hub).

Lens

Choice of lens and visual angle is on of the most important

decisions in designing a machine vision system. Common types of lenses

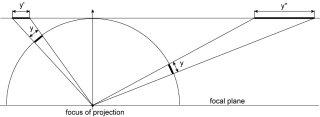

reflect the image into area with so-called perspective projection.

This compels us to deal with features of projective imaging of

three-dimensional scene into two-dimensional area of image sensor's

surface. Lens field of view is in this case formed by viewing

truncated cone. Rectangular area of the image sensor further reduces

this cone into viewing pyramid. Its peak is called the focal point of

the projection. When converting a scene image inside viewing pyramid

into image area, there is considerable loss of information. Each

half-line passing through the focal point of the projection is in the

image area represented by a single point.

Even the theoretical assumption of a perfect lens with linear

transfer from angle to position and planar two-dimensional scanning of

the pattern, we have to deal with distortions of image geometry due to

perspective errors. Imagine a picture of dark dots on a light

background with a constant spacing of dots in the axes x and y. To

achieve a constant spacing of dots provided accurate perspective

projection even in the projected image, the pattern must be scanned

from the inner surface of the spherical area. When the planar pattern

spots in the projected image will move away from each other depending

on their distance from the optical axis.

Distortion of the geometry of planar image in perspective

projection Loss of spatial information in perspective projection complicates

e.g. the exact measurements of sizes of three-dimensional objects.

Without prior knowledge of taken subjects shapes we are not

additionally able to correct these errors. Even with knowledge of the

object's shapes, the correction of projective errors requires

identification of objects of machine vision software equipment,

therefore a high level of image understanding is required. In addition

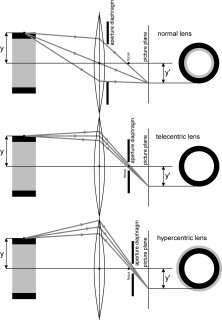

to normal lens with a perspective projection, there are also special

lenses with orthographic projection. These lenses do not display a

scene with a focal perspective, but with a perpendicular parallel

projection. So, the size of the displayed items are always the same,

regardless of their distance. That sounds like a good solution to all

problems with accurate measurements in the image, but it has one

problem. In this type of projection the size of the lens input

surfaces must be similar to the area of scanned scene. These so-called

telecentric lens are then very large and expensive. The principle of

telecentric lenses is quite simple. With aperture diaphragm located in

plane of image main point (outbreak lenses) all the rays coming from

other directions than parallel to the optical axis are blocked.

The projection principle of normal, telecentric and

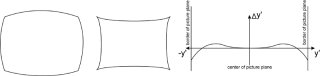

hypercentric lens In order not to end all problems, significant limitations of

measurement accuracy in the image can cause the geometric distortion

of image field of lenses, and they occur even at telecentric lenses.

By distortion we mean the difference between the theoretical position

of a pixel, which derives from the principle of projection and the

actual position of point displayed by an actual lens. At the actual

lenses there is never a transfer between the angle position (or

distance) of an object from the optical axis and between the image

distance of the object in the image area completely linear. Angle

transformation at distance has quadratic character, but more often,

the cubic polynomial. When using with several-megapixel cameras, even

a very good lens has usually radial distortion in the range of units

to tens of pixels. In some applications, such as when we read texts,

codes or count components, it does not have to matter. In applications

where is the required precision of measurements, the lens quality

becomes a crucial factor.

The usual geometric distortion of image field While with the principles of projection we cannot do anything,

distortion of image field can be corrected by software and we can

achieve outstanding sub-pixel accuracy with standard lenses. The

problem may be computational complexity of correcting algorithms. For

example, VisionLab system carries out these corrections using the GPU

with quite minimal impact on computers workloads.

Lighting

While in the preceding paragraphs it is possible to estimate the

right solution intellectually very well in advance, and often to

accurately calculate, the correct choice of lighting requires

considerable experience and often a lot of experimentation. Especially

if the scene consists of transparent, shiny or embossed unremarkable

objects, lighting design is the key of overall success. We must choose

the type, number and position of lighting units and the color of their

light. Often it is necessary to solve blocking an unwanted light from

the surroundings by shading and color filters in the camera. The

polarizing filters can contribute to a significant reduction of

unwanted reflections .

Cheap lighting can be solved e.g. by using fluorescent tubes,

possibly even without electronic ballasts, but the camera must be able

of sufficiently long exposure times. More quality and better

parameterizable lighting provide light-emitting diode units, whose

price has been reduced so much that is usually not an obstacle to

deploy them. If operating the lighting during the activity is needed,

e.g. setting brightness, colors or initialize flashes, it is a great

advantage to have an option of operating the lighting units directly

from cameras.

In conclusion

If we did not leave anything substantial in the previous steps, it

remains only to choose appropriate software for image processing and

understanding (and of course everything to configure and program) and

the success of the contract should no longer be endangered.

DataCam digital industrial camera offer interesting properties for

use in machine vision systems. It is a low-noise CCD cameras, which

provide clean raw image data in sixteen bit dynamic pixel brightness.

Are connected to a computer via USB cable, from which are

simultaneously powered. Cameras excel in image quality and

clarity.

DataCam digital camera Each of these cameras can directly control up to four DataLight

lighting units, which are available in the form of a circular

illuminators, area illuminators, flash illuminators and illuminated

panels. At DataLight units, we can choose color and emissive angle of

diodes and possibly the presence and type of diffuser.

DataLight lighting units with DataCam camera At the top of the pyramid schemes of components for machine

vision stands software, which is able to understand images. Richly

featured VisionLab system aims to facilitate the creation of most

machine vision applications and easy integration of applications

into the IT organization. Its advantages include:

easy integration of digital images and visual inspection for

applications in industrial automation intuitive steps editing of machine vision chain support of fully parallel processing on multiple cores and

multiple CPUs support of massively parallel image processing by

GPU advanced image adjustment by GPU

Morphological image transformation can be implemented

on the GPU using the data stream from the cameras in real

time image data transmission in computer networks image data archiving in the form of images and video open interface for adding steps for machine vision sharing data with the applications of the Control

Web system

RC

|