|

The Ethernet was in minds of technicians for a long time connected

with shared transmission medium in the form of thick and thin coaxial

cable or hub with wide collision domains and above all with

nondeterministic principle of collision solution by CSMA/CD (Carrier

Sense with Multiple Access and Collision Detection). All stations in

collision domain can receive together, but only one can transmit. If

there is a collision, caused by transmitting of more than one station,

all stations turn off for random period of time, before any of them

tries it again. At low network load, this very effective method caused

exponential increase of collisions when increasing the load.

These problems disappeared by the start of using switches.

Nowadays, the collision domain usually contains only two participants

- end device and switch. Cables contain up to four twisted pairs and

transmission runs concurrently witháreceive ináfull duplex

mode. Transmission medium is not shared and it does not make any

collisions. Transmission speed can steadily reach the most possible

level. Such network can be decent basis of communication even for very

complicated and extensive automation systems.

As well as the Ethernet represents the best variant for wide

networks, in case of connecting peripheral units to computers, the

best choice is USB connection. This standard of universal serial bus

originated in 1995 and its quicker variant USB 2.0 withá480

Mbit/sábit rate exists more than ten years too. USB represents

obvious qualitative progress against all formerly used serial and

parallel interfaces. Its reliability, endurance, transmission speed

andáresponse time predetermines it for majority connected

peripheral units inátask of data collection and industrial

automation.

Ethernet nor USB are not new and untried technologies. These

standards did not have an easy way to the branch of industrial

automation. Their dominance is obvious and their qualities

indisputable. Building an Ethernet network is actually extremely easy,

cheap and quick and all system integrators handle this task without

difficulties. Andábuilding a network of peripheries communicating

over USB is even easier.

Serious requirement on communication ináautomation systems is

working ináreal time. Working in real time does not require only

short responses and high speed transmissions, but above all,

deterministicity. It means, the system must guarantee the response in

requisite time - and time response requirements differs case-by-case.

The guaranteed time response is related to stability of time response

as well. The requirements on tolerance of time response significantly

differ in single applications.

According to time requirements and the requirements on

stability of time response of communication network, it is possible

to distinguish approximately three types of industrial Ethernet

network:

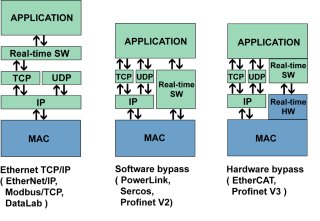

Real time is solved through software under standard layers

IP, UDP a TCP. This organization works in all standard networks and

they reach time responses counted in milliseconds with the right

segmentation of the network. This standard architecture is the

cheapest, easiest to realize and satisfy in the majority of

industrial networks. As an example of such solutions is e.g.

Modbus/TCP or DataLab. Real time is solved through software substituting standard

layers IP, UDP a TCP. These networks work with standard network

adapters, communication software works in real time directly under

Ethernet packets and in reserved segments of network reaches

responses andáprecision suitable even for iápro demanding

applications e.g. onáarea of drives and robotics. The highest requirements on real time are solved by

combination of special hardware and software. It is impossible to

use standard network adapters here and these networks usually work

with its own identification of single nodes without necessity of

assigning IP addresses. Communication packets are not usually read,

interpreted and consecutively further posted, but permeate through

by single node witháminimum delay counted in nanoseconds to

another device. Data are given on reserved space in data telegram,

which circle on network. Real time communication packets have the

priority in network before packets of standard network layers IP,

UDP and TCP.

Three principles of solving the communication in real time

in Ethernet networks In different network solutions of industrial Ethernet is

for keeping the demands on punctuality of message delivery able to

use:

star structure witháswitches and not with hub communication models publisherá/ásubscriber and

producerá/áconsumer instead of clientá/áserver

model priority Ethernet packets high-speed variants of Ethernet network segmentation synchronization on principle of distributed real time

hours

Ethernet network is important medium for connecting and integration

of many automation applications into one scope with the option of

central management and supervision. Single applications within the

enterprise can work independently without the necessity to communicate

with other systems in real time and yet can be part of one centrally

managed complex. Stand-alone applications do not have to have their

own displays or any other human - machine interface, they can be

equipped by uninterruptible power supply and can permanently run

irrespective of the state of company computer network.

Applications, which have no displays of their own nor even own

computer, can be run in the environment of the Ethernet network.

Aánumber of stand-alone applications can run on single dedicated

server. The management and maintenance of system becomes even more

simple and it is also possible to spare considerable finance on buying

a upgrading computers and control units. The reliability of network

infrastructure here is substantive, but nowadays it is not usually a

problem.

Connection over Ethernet:

+ practically unlimited distance of connection (dedicated

segment withátwisted pair to circa 100 m) + time response counted in milliseconds - power supply is not always part of communication standard (

standard Power over Ethernet defines options of power supply of

Ethernet devices through data conductors from CAT5 cabling, voltage

of 44 ľ 57Vá is usually used with max. current of 550 mA

) - it is necessary to assign fixed IP address - it is necessary to configure the device through inbuilt

HTTP server before the first use

Connection over USB:

+ time response counted in milliseconds + high transmission speed 480MB / sec, sufficient

transmissive capacity even for high definition digital

cameras + power supply is fixed part of bus + plug-and-play without the necessity of

configuration - the distance of connection to 5m (witháactive

extension to circa 30m)

DataLab IO/ETH units with Ethernet interface are fully compatible

with all I/O modules of DataLab IO system. Only USB interface is

replaced by 10/100 Mbit Full Duplex Ethernet interface and the unit

communicates through TCP/IP protocol. TCP/IP protocol can be easily

routed through various network, the physical distance of the unit from

a computer is practically not limited. From the point of view of

application program equipment, the USB and Ethernet units do not

differ. It suffices in parametrical file of identical driver to choose

the way of communication and set the proper addresses. Then the

applications communicate identically with single units. The

communication with Ethernet units is encrypted and that prevents from

unauthorized interventions in the technology.

The components for industrial automation with the option of

Ethernet and USB connection make integration of applications to

connected centrally managed environment easier and make the building

of modern integrated systems significantly cheaper.

rc

|