|

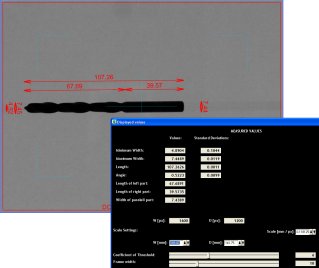

The inspection system captures image of each drill or mill tool and

also reads its weight. Geometrical dimensions of the particular tool

are then measured from the image. Then it is possible to calculate

material type and also the area of coated parts of the tool from the

dimensions and weight. Each tool is identified and characteristic

dimensions are checked.

The first precondition for achieving of high precision is capturing

of high-quality, high-resolution image, not distorted by noise or

lossy compression. This particular system uses 2 MPx DataCam

DC 2000 digital USB camera, which fulfills all requirements with

wide margins.

Then it is necessary to eliminate all lens aberrations and radial

image distortions, distortions caused by perspective projections and

lighting effects. Precise, but huge and expensive telecentric lens

significantly rises the application cost. This particular application

employs rather common Fujinon lens with C- mount. All image

distortions caused by lens and perspective projections are eliminated

with sub-pixel precision using image processing components of the

Control Web software. All these processing results

into absolute precision and reproducibility around 0.03 mm. Tools

can be measured with similar precision anywhere within the camera

field of view.

Thanks to Control Web rapid application

development system this application can be easily integrated into any

enterprise information system. Control Web

application is also easily maintainable and extensible.

Standard deviations of multiple acquired

dimensions The whole application demonstrates the capabilities of the DataCam

cameras integrated with Control Web image processing

components to create high-quality solutions with very affordable

prices.

rc

|