OPC as Communication Layer in Industrial Automation

The basic principle is quite simple. The Control Web application connects to the OPC server using the OPC

client (driver). The OPC server stores the data written by

Control Web and allows other clients to read

them. Similarly, Control Web application can read

data stored on OPC server, written by other clients. The OPC

server should have the capability to store data items—the OPC server for Control Web

drivers can provide this feature by very simple OPC Storage

Driver, which is supplied with the server.

OPC Server for Control Web Drivers

The OPC server for Control Web

drivers is quite new product. It uses drivers compatible

with Control Web to communicate with industrial

devices. That means the OPC server can provide OPC interface for

every industrial device, for which the Control Web driver exists.

The OPC Storage Driver is included as a part of the

product beginning from version 1.2. This driver does not

communicate with any I/O device, it only stores values

written to its channels and allows reading of these values.

A kind of data storage is then created by the driver. This

storage can be used to pass data among various OPC clients. All

clients connected to this server share the same values.

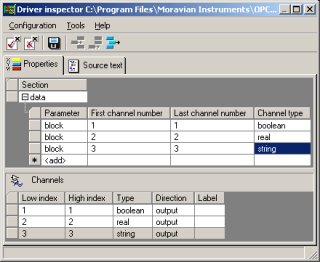

Channels, their numbers and data types are defined during

driver configuration. This process also defines the size and type

of data storage. The following image shows driver

configuration.

Data storage driver configuration If the driver is connected to the OPC server, all its channels

become a part of the server's name space. It is of course

possible to connect multiple storage drivers to the OPC server

(the number is not limited) so it is possible to create multiple

storages on single server.

OPC Server as Data Storage

The OPC server is not used for communication with any

particular I/O device, but only to exchange data among

different software layers. It is of course possible to combine

both ways—one OPC server can act as a data

storage and also can communicate with hardware devices.

It is also possible to access the OPC server from remote

computers (on the LAN) thanks to the DCOM (Distributed COM)

technology. So the access to data storage as well as hardware

devices is not limited to single computer.

Example

Let's demonstrate a simple example of the whole system

configuration—creation of Control Web 5 application and OPC server configuration. Our task

is to allow access three variables (logical, numeric and string),

defined in Control Web 5 application, by OPC

clients.

Step 1—Installation

It is necessary to install the following products

in the first step:

Control Web 5 The

Control Web Runtime should be installed for

real application, but the development and testing should be

performed in the development version of Control Web 5. The OPC client driver for Control Web 5 OPC server for Control Web

drivers

Appropriate license numbers must be entered and all

products must be activated. Individual product documentation

describes these steps thoroughly.

Step 2—OPC Server

Configuration

It is necessary to define OPC server parameters now.

First it is necessary to create data storage, that means to

define data elements, which will be used to exchange data. We

need to create three data elements: logical, numeric and

string.

Run the OPC server and open its configuration window (if

the OPC server is run for the first time after installation,

it opens configuration window automatically). Run the

Device connection wizard (menu item

, ). Enter the data

storage name in the first step, for instance demo.

Choose the OPC Storage driver from the list of

available drivers in the next step.

The driver configuration is run when the wizard finishes.

We must add three new items in the sheet (click the text

add) and set the channel type according to the

following figure.

It is necessary to store the OPC server configuration now

(menu , ).

Step 3—OPC Client Driver for

Control Web 5 Configuration

We will configure the OPC client driver for Control Web 5 in the next step. Run the OPC Driver

Configuration Tool (choose the ,

from the Windows

, menu).

Connect the configuration tool application to the OPC

server (menu , and select Control Web driver OPC DA

v 2.0 server).

There is a tree of all data elements offered by the

connected server on the left side of the configuration tool

window. Insert all three data elements (1, 2 and 3) to driver

configuration (double-click the element name in the tree).

Assign channel number to all elements (the Channel

number column in the sheet). The configuration is shown

on the following figure.

Channels are used for exchanging data with the device

(using the driver) in the Control Web

environment. Thus channels allow communication between

application and OPC server. Every channel is uniquely

identified by a number in Control Web— 1, 2 and 3 in our

case.

Save the configuration now (menu ). Two

files are created on the disk—one with

PAR extension and the second with DMF extension. These files

are used when creating Control Web

application.

Step 4—Control Web 5 application

Run the Control Web 5 and create new

application. Insert the OPC driver into the application and

use the already created PAR and DMF files for its

configuration. Name the driver for instance opc.

Add three virtual instruments into the application in the

next step. The switch instrument sets logical

value, the control instrument sets numeric

value and the string_control instrument sets

string value. Define the output property of all

instruments and set the appropriate driver channel as its

value. For instance the switch instrument will

have the output properly defined:

opc.1

This instrument will write to the first channel. OPC client

driver will pass the value to the OPC server. OPC server

stores the value to the data storage and allows other OPC

clients to read it.

Conclusion

Although the configuration requires some steps to be performed,

it is not very complicated. Control Web

application data can be easily accessed by other OPC clients

now.

Another OPC-related articles:

|